Flat face the hammer head doesnt hit the shingle squarely

Also covered are the general, industry-accepted methods for installation, where to look for defects, how to recognize them, and how to determine how serious they are. Using a forensic approach to inspecting asphalt shingles, you’ll learn to compare what you see to what you know.

ASPHALT SHINGLE COMPONENTS

All modern shingles manufactured in North America have mats made of interwoven fiberglass strands, so you may also hear them called "fiberglass" shingles. A modern shingle consists of a fiberglass mat embedded in asphalt, and covered with granules on the surface that faces the weather. The mat, asphalt and granules act together to form a durable, flexible and waterproof assembly.

In the past, shingles were also manufactured using mats made of cellulose-based materials, and these are called "organic" shingles.

Fiberglass shingles are designed to be resistant to heat and humidity. Warm air can hold more moisture than cold air. Because they absorb less moisture, fiberglass shingles deform less as they age, making them more stable in warm or damp climates.

Also, because the fiberglass mat does not absorb moisture, as fiberglass shingles age and lose volatiles, they deform less than cellulose shingles. “Volatiles” are compounds in asphalt that help keep shingles waterproof, flexible and durable, but which dissipate over time. Most volatile dissipation is due to evaporation from overheating.

Page 3 of 123

Student Book

Inspecting Asphalt Shingle Roofs

Online Video Course

InterNACHI

Because of their thicker, flexible, double-asphalt layer, organic shingles can be more durable in cold climates than fiberglass shingles.

Distortion

Since organic shingles near the end of their life can hold considerably more moisture than fiberglass, they can exhibit extreme distortion.

ASPHALT

Student Book

Inspecting Asphalt Shingle Roofs

Online Video Course

InterNACHI

Thickness

Student Book

Inspecting Asphalt Shingle Roofs

Online Video Course

InterNACHI

Back-Surfacing

Granules embedded into the weather surfaces of shingles are made from fine-grain, opaque, crushed rock particles. Opaque granules don’t allow light to pass through.

The uniformity with which granules are applied can affect the way they look on the roof. Granules have four main purposes:

|

|---|

The adhesive strip is the most important component in providing wind resistance for a shingle roof. Bonding shingles to each other helps them resist uplift and keeps them lying flat so that they expose the minimum amount of surface for the wind to push against.

This bond also helps seal the roof against moisture intrusion and allows the shingles to act, to some degree, as a single, water-resistant membrane.

Page 8 of 123

Student Book

Inspecting Asphalt Shingle Roofs

Online Video Course

InterNACHI

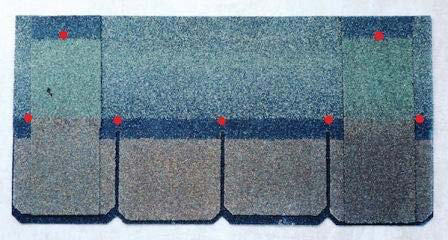

This is a three-tab (or 3-tab) shingle. It’s a type of strip shingle.

Its main identifying featureis two notches, called cutouts, which separate the lower part of the shingle into three tabs, as you can see here. A three-tab shingle is a single layer thick, usually 12 inches wide and 36 inches long. Metric shingles are a little larger but are less common in the U.S.

Page 9 of 123

Student Book

Inspecting Asphalt Shingle Roofs

Online Video Course

InterNACHI

Laminated shingles typically come in metric sizes, measuring about 39 x 13 inches.

Laminated shingles with 30- to 50-year warranties typically weigh250 to 300 pounds per square, and are designed with a maximum wind resistance of 70 to 110 miles per hour.

Here’s an example of a high-quality laminated shingle. Some of the more expensive laminated shingles may have up to five layers and weigh close to 500 pounds per square. These shingles may be designed to withstand winds of up to 130 miles per hour.

Interlocking Shingles

CALCULATING and PACKAGING SHINGLES

The amount of asphalt shingles required to cover a roof is calculated by the square. A square is an area 10x10 feet. Shingles are sold by the bundle, and a square may contain from three to six bundles, depending on the shingle design and exposure.

This device has a tapered slot lined with calibration marks that show the warranty connected with the shingle thickness. You won’t be able to positively identify the warranty of the roof, but using the gauge allows you to get a good estimate.

Page 12 of 123

Student Book

Inspecting Asphalt Shingle Roofs

Online Video Course

InterNACHI

Generally speaking, people from three different industries are likely to be inspecting asphalt shingles: insurance claims adjusters; roofing contractors; and home inspectors.

Because of the many factors that can affect the condition of asphalt shingles, it’s not always clear whether a defective condition or functional damage exists. Conditions are not always obvious or either right or wrong.

In this training course, “damage” is divided into two categories: functional damage and cosmetic damage.

Functional Damage

With asphalt shingle roofs, insurance companies typically don’t pay for cosmetic damage.

Page 14 of 123

Following the manufacturer’s recommendations helps maximize the long-term service life.

Manufacturers of a particular type of shingle know best how it will react to damaging and deteriorating forces. They’re better equipped than an outside agency at choosing the installation method which will best maximize the shingles' long-term service life. This makes sense in light of the fact that manufacturers issue warranties and have to stand behind their products. Contractors and installers who do not follow manufacturers' recommendations, but, instead, rely on their own past experience, may diminish the quality and workmanship of roofs so that the structures may not perform as well or last as long, had they followed the manufacturers' recommendations during installation.

Student Book

Inspecting Asphalt Shingle Roofs

Online Video Course

InterNACHI

During some roof inspections, you’ll often find newer shingles installed right over old roof-covering materials. Multiple layers get hotter and hold heat longer, so shingles won’t last as long, although the roof is less likely to leak. Shingles installed over other shingles will also not have a valid manufacturer’s warranty.

Roof slopes that face the prevailing winds and storm approaches may also deteriorate more quickly than protected slopes.

Roof Design

Steeper pitches shed water faster, reducing the chances of leaks and ice-dam formation.

Student Book

Inspecting Asphalt Shingle Roofs

Online Video Course

InterNACHI

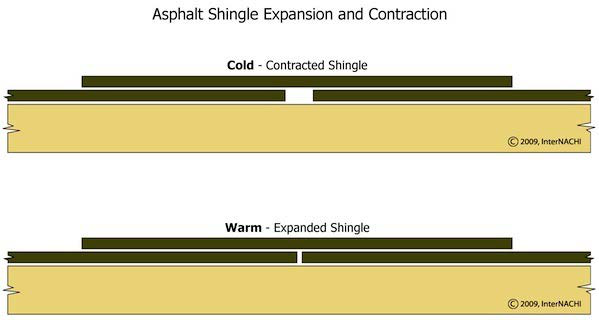

dormers, help limit expansion and contraction. Large amounts of expansion and contraction can cause problems, especially when the materials that are fastened to each other, such as roof sheathing and asphalt shingles, expand and contract at different rates.

As shingles age, they shrink. This is especially true of organic shingles. As they shrink over the warm part of the year and contract with the cold, shingles that bridge a joint between underlying shingles may split.

The amount of thermal cycling experienced by shingles may be affected by:

Home Site Conditions

Different home site conditions can create different types of problems.

Student Book

Inspecting Asphalt Shingle Roofs

Online Video Course

InterNACHI

Roofs shaded by trees or mountains may stay cooler or may stay excessively moist, which can lead to microbial growth.

Shingles on homes at higher elevations are exposed to more ultraviolet radiation than homes at lower elevations. Since UV radiation damages the asphalt layers of shingles, shingles installed at higher elevations may have a shorter long-term service life.

People may not understand the importance of maintenance, or they may not know what type of maintenance is required. They may not be able to perform the maintenance themselves, or they may not be able to afford to pay somebody else to do it. They may procrastinate; maintenance may just be low on their list of household priorities.

Failing to perform maintenance, such as cleaning the roof and gutters and repairing roof damage, can shorten the service life of the roof and damage home materials. You’ll see plenty of deferred maintenance as you inspect roofs.

There are six common, general sources of problems. The first is installation.

Installation

What constitutes proper installation of these three components varies according to who manufactured them and what part of North America the home is located in. Installation may be affected by building codes, too.

Building Codes

Student Book

Inspecting Asphalt Shingle Roofs

Online Video Course

InterNACHI

Student Book

Inspecting Asphalt Shingle Roofs

Online Video Course

InterNACHI

UNDERLAYMENT

Let’s discuss underlayment.

Missing or improperly installed underlayment can void any warranty that might be in effect.

Underlayment Installation Requirements

The IRC and shingle manufacturers generally agree on underlayment

requirements, which are the same for felt and synthetic types.

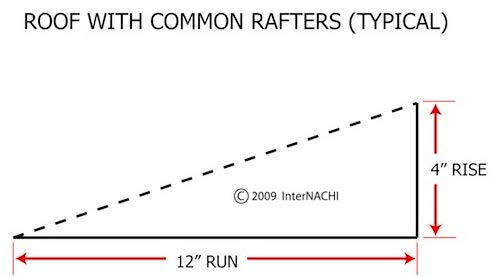

The angle of slope is described by the number of inches the roof rises in each horizontal foot. So, a roof that rises 4 inches vertically for every 12 inches of horizontal is said to have a 4:12 pitch.

Steep-Slope Roofs

Roof slopes of less than 4:12 down to 2:12 are called low-slope

roofs. Two layers of

underlayment are required for low-slope roofs. The first course is

doubled. Above that, 36-inch wide strips are then applied to the roof in

a shingle fashion, starting at the lower roof edge, and overlapping

subsequent courses a minimum of 19 inches.

Page 26 of 123

Remember that underlayment on steep-slope roofs should overlap 2 inches. Also, remember that asphalt shingles should never be installed on roofs having a slope of less that 2:12.

Fasteners

In areas that are subject to high winds, underlayment is sometimes fastened with windstrips, which are designed to resist tearing.

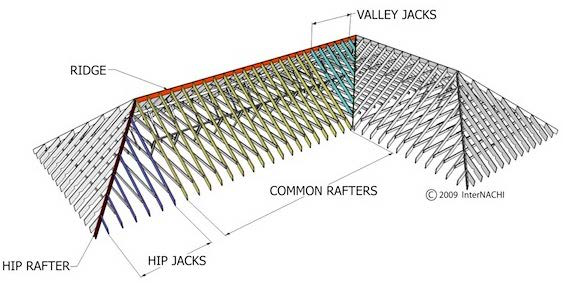

Valleys are created where two roof slopes meet. Valleys are

especially vulnerable to leakage for three reasons:

1. concentrated runoff: The combined runoff from both

roof slopes is concentrated in the valley, so valleys carry more runoff

than other parts of the roof;

2. interrupted roofing: The roof-covering materials are

interrupted by the change in roof direction. Any interruption in the

roof-covering material increases the opportunity for leakage; and

3. less slope: Although they carry more runoff, valleys

slope less than the surrounding roof, so, in addition to carrying more

runoff, they drain it more slowly. The chances for leakage increase as

the slope of the roof decreases.

The reason for this is that, although valley rafters rise the same total distance as common rafters, they do it over a longer distance because valley rafters are oriented diagonally to the ridge, and common rafters are oriented perpendicular to the ridge.

Student Book

Inspecting Asphalt Shingle Roofs

Online Video Course

InterNACHI

FLASHING, Part 1

The IRC requires roof flashing to be installed in the following locations:

|

|---|

ROOF-WALL INTERSECTIONS

Places where roofs and walls intersect are called headwalls and sidewalls.

A headwall is a junction where the top of a sloped roof meets a wall.

Headwall flashing should extend up behind the exterior wall covering and down over the shingles, as you see here. This image shows counter-flashing installed behind the siding. Sometimes, the exterior wall-covering material serves as the counter-flashing, and this is acceptable.

Page 33 of 123

Headwall flashing typically comes bent to 120 degrees. It can be easily flattened for roofs with shallower pitches.

Page 34 of 123

Sidewalls on roofs covered with asphalt shingles should always be flashed using step-flashing. A step-flashing is a short section of flashing that overlaps each shingle in the course below and is overlapped by each shingle in the course above.

Student Book

Inspecting Asphalt Shingle Roofs

Online Video Course

InterNACHI

Although you may sometimes see counter-flashing installed, it’s more common that the exterior wall covering acts as the counter-flashing. The exception is brick.

Page 36 of 123

Student Book

Inspecting Asphalt Shingle Roofs

Online Video Course

InterNACHI

Considering the age of this home, it may have been correctly flashed when it was first built, but the original flashing may have failed due to corrosion.

Wall-Covering Clearance

You’ll often see siding and stucco installed right down on top of the shingles. Without a gap, the exterior wall-covering can wick up moisture from the roof. This can lead to decay, delamination, peeling paint, and other problems. This condition is especially common on roofs with multiple layers of shingles.

Page 38 of 123

Counter-Flashing at Brick Walls

Headwall and sidewall flashing installation becomes more time-consuming to do correctly when the exterior wall covering is brick.It is also more expensive to do, which is why most of the counter-flashing you’ll see at brick walls is poorly installed and relies on a sealant alone to prevent moisture intrusion. Sealant eventually dries, shrinks and cracks, leaving an avenue for moisture intrusion.

Page 39 of 123

Student Book

Inspecting Asphalt Shingle Roofs

Online Video Course

InterNACHI

This particular kickout is bigger than most you’ll see. Usually, the kickout is cut from a piece of the step-flashing.

The purpose of the kickout flashing is to prevent runoff from entering behind the exterior wall-covering where the flashing ends.

Student Book

Inspecting Asphalt Shingle Roofs

Online Video Course

InterNACHI

A kickout is easy to fabricate on site. A piece of step-flashing is cut partially through one flange, and the corner is clipped off.

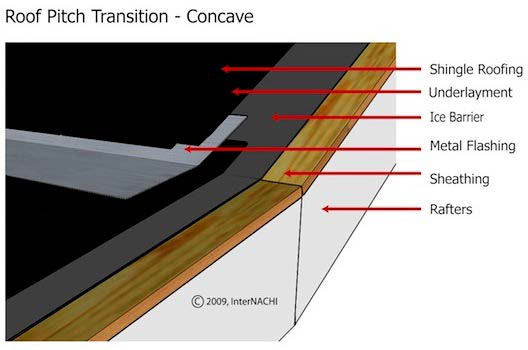

Changes in Pitch

Page 42 of 123

Student Book

Inspecting Asphalt Shingle Roofs

Online Video Course

InterNACHI

A flashing detail common to all penetrations is that flashing is overlapped by the roof-covering material on the uphill side and overlaps the roof-covering material on the downhill side.

Skylights

Student Book

Inspecting Asphalt Shingle Roofs

Online Video Course

InterNACHI

Page 44 of 123

Student Book

Inspecting Asphalt Shingle Roofs

Online Video Course

InterNACHI

|

|

|---|

We know that valleys are especially vulnerable to leakage, so let’s look at the different types and the methods used to construct them. You’ll see two basic types of valleys: open and closed.

Open Valleys

You’ll see two kinds of closed valleys: cut valleys, which the most common, and woven valleys.

Because valley linings for closed valleys are protected by the shingles, the linings are not exposed to weather, abrasion or impact, and may be made of thick underlayment or thinner metal than that used for open valleys.

Courtesy of CertainTeed®

With cut valleys, shingles from one roof slope extend several feet onto the adjacent slope, and shingles from the adjacent slope are cut parallel and just short of the center of the valley. In good installations, the top corner of the shingles are clipped to help route any cross-wash back into the valley.

Page 46 of 123

Student Book

Inspecting Asphalt Shingle Roofs

Online Video Course

InterNACHI

As work progresses, additional valley shingles are added. To spot this type of valley, look at the bottom of the valley for the triangular shape of the butt of the first valley shingle installed.

Woven Valleys

In roofs with woven valleys, shingles from both roof slopes run through onto the adjacent slope, alternating with each course. You’ll see this done differently with different types of shingles. It should be done in a manner which will prevent runoff from penetrating the shingles.

Here are some concerns about woven valleys:

• On newer homes, also mention that it may void the manufacturer’s warranty.

Page 48 of 123

Courtesy of CertainTeed®

This diagram shows a conventional offset installation. The amount of offset varies with the model of shingle.

This diagram shows shingles installed using the racking method.

FASTENERS

One of the key components in the wind resistance of shingles is the fasteners that hold them to the roof.

The type of fastener used to fasten the shingles is especially important in resisting wind uplift and pull-through. Fasteners for asphalt shingles should be roofing nails or staples. The head of a roofing nail or the crown of a staple is what actually holds a shingle in place.

Although both nails and staples have been used in the past, staples are often not recommended in areas subject to high winds, and they are not allowed in new construction by the IRC.

To hold properly, staples need to be installed with the crowns aligned with the long axis of the shingle. As an installer uses an air-powered staple gun, his natural tendency is to rotate his body.

Page 51 of 123

This roof has staples that were poorly installed, and the shingles were poorly bonded, so their wind resistance was low.

The minimum staple crown width is 15/16-inch. Properly installed, stapled shingles will usually withstand wind speeds of up to 60 miles per hour. Upgrading the fastening system requires re-fastening the shingles with roofing nails. The shingles may need to be hand-sealed afterward, since the adhesive bond may not re-seal adequately.

Nails should be corrosion-resistant. Corrosion-resistant nails include galvanized, copper, aluminum and stainless steel.

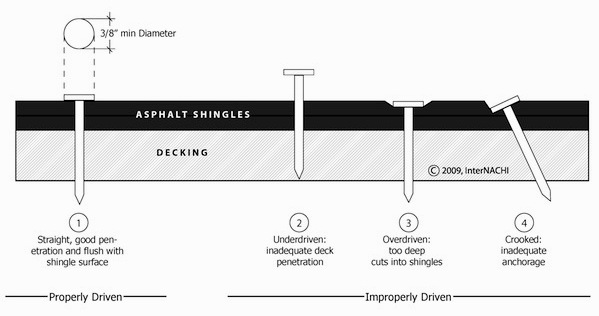

The minimum nail head diameter is 3/8-inch. Nails must be long enough to penetrate through the sheathing.

Longer nails are required under certain circumstances, such as:

Nails and staples have to be driven to the proper depth.

Page 53 of 123

The same is true of staples. Over-driving, under-driving, and driving staples at an angle can be even more of a problem than with nails due to the shape of the staple crown. Again, with staples, proper crown orientation is crucial to maintaining wind resistance. Staples should be installed with the crowns parallel to the long edges of the shingles.

Fastener Placement

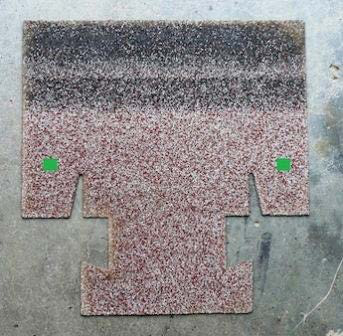

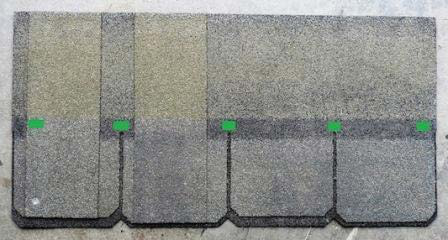

The green areas on this 3-tab shingle show the typical nail placement on homes in areas with normal wind conditions.

Student Book

Inspecting Asphalt Shingle Roofs

Online Video Course

InterNACHI

Page 56 of 123

Student Book

Inspecting Asphalt Shingle Roofs

Online Video Course

InterNACHI

High-nailing is common, and you should remember that, even though you’ll see it often, high-nailing is improper installation and should be described that way in the report. Correction involves placing nails in the proper locations and hand-sealing the affected shingles because, once the adhesive strips have been broken loose, they may not re-seal themselves adequately.

These heavy, laminated shingles have different fastening requirements. This is the recommended fastening for roofs with pitches less than 21:12.

Exposed nailswill corrode over time, and expansion and contraction may eventually expand the nail holes enough to allow leakage. Shingle manufacturers recommend replacing any shingles with exposed fasteners. They consider caulking nail heads to be a temporary repair.

Page 59 of 123

Confirmation is impractical for two reasons. First, fastening schedules vary with different models of shingles. As an inspector, you won’t know the fastening requirements unless you identify the manufacturer and model of the shingles on the roof, and research the fastening requirements. Maybe that information will still be available somewhere, but maybe not. Trying to find it may use up a lot of your time that your client may or may not pay for. Second, the only way to confirm proper fastening of an entire roof is to break the bonds of all the adhesive strips on the roof, and that will damage the roof. Breaking the bonds would seriously compromise the wind resistance of the roof and could easily damage it permanently.

If you want to check for proper fastening in a representative number of places, after breaking the bond, you’ll need to hand-seal any affected shingles to help ensure that they fully re-bond. At best, it will take time for any bonds you break to re-seal. If the weather is cold, re-sealing may take months.

When it’s time to install a new roof, homeowners face the choice of whether to have the existing shingles removed before installing new ones. Most jurisdictions limit the number of layers allowed on a roof before removal of all layers is required prior to installing new shingles. In most places, the maximum is two or three layers. In a few places, it’s only one layer.

Installing new shingles over old has some disadvantages:

|

|---|

Telegraphing is even more obvious when asphalt shingles have been installed over wood shingles. As runoff flows down the roof, this unevenness can create areas of increased friction, which results in premature failure of the new roof over those areas.

Page 61 of 123

Student Book

Inspecting Asphalt Shingle Roofs

Online Video Course

InterNACHI

Page 62 of 123

Student Book

Inspecting Asphalt Shingle Roofs

Online Video Course

InterNACHI

Bridging

Using the “bridging” method, shingles are installed starting at the

lower edge of the roof as if they were being installed directly onto

sheathing. They’re installed with the exposure

recommended by the manufacturer. There will be unsupported areas beneath

the new shingles where they bridge the butts of the old shingles, as you

can see here. These voids are especially vulnerable to damage from

impact.

In this example of bridged shingles, you can see the tops of new shingles overlapping the butts of the existing shingles.

Nesting

Student Book

Inspecting Asphalt Shingle Roofs

Online Video Course

InterNACHI

ASPHALT SHINGLE WEATHERING

Degree of Roof Slope

Flatter roofs have shorter lifespans because they shed moisture more

slowly and are more directly exposed to UV radiation than roofs with

steeper pitches.

Climate

Harsh climates shorten roof lifespans. Wind, moisture and thermal

cycling all contribute to deterioration of roofing materials.

Quality of Maintenance

Failure to repair damage and keep roofs clean can result in damage and

deterioration from moisture intrusion and wind.

Page 65 of 123

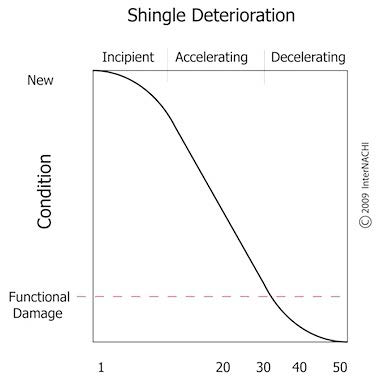

The lifespan of asphalt shingles is related to the rate at which they deteriorate. The long-term deterioration pattern of an asphalt shingle can be broken into three parts:

By the time the deterioration curve begins to flatten out and the decelerating period begins, the shingles have reached the point of functional failure. They’re no longer protecting the roof and are trying hard to turn back into the raw materials from which they’re manufactured.

Page 66 of 123

The difference between splitting and cracking is that a split goes entirely through a shingle, and a crack is limited to the surface of the asphalt layer.

Student Book

Inspecting Asphalt Shingle Roofs

Online Video Course

InterNACHI

The second assemblyis formed by the shingles that are bonded to each other by adhesive strips and which, structurally, may act as one big shingle if the adhesive bond is strong enough.

These components are all attached to each other, so why not call them one assembly?

Rafter sheathing and roof trusses are made of wood and will react in a manner similar to changes in moisture and temperature.

2. They have different functions. The rafters and sheathing are part of the building structure and, when properly built and maintained, have a much longer design life than the roof-covering material. Roof framing is not designed to withstand direct exposure to weather.

Shingle splitting due to temperature-related expansion and contraction is called thermal splitting. Thermal splitting typically happens where shingles bridge the joints in the underlying layer of shingles.

If the adhesive strips bond shingles together strongly enough, the shingles on a roof slope can act almost as a single membrane.

The shingles that bridge those underlying joints are shrinking, too, and these bridging shingles becoming increasingly stressed as the entire bonded-shingle assembly continues to shrink.

If this stress exceeds a critical point, one of two things will

happen:

1. If the strength of the bond of the adhesive strips exceeds the

tensile strength of the shingles, the shingles bridging the joints will

split, creating an opportunity for leakage to develop. 2. If the tensile

strength of the shingles surpasses the strength of the adhesive bonds,

the bonds will fail, drastically lowering the wind resistance of the

shingles.

Student Book

Inspecting Asphalt Shingle Roofs

Online Video Course

InterNACHI

HAIL DAMAGE

You will not be able to determine the impact rating of shingles by looking at them, although the impact rating is usually marked on the cellophane on the underside of the shingle.

There are several methods commonly used today:

A third method is to modify the asphalt mix by adding polymers. Polymers are chains of molecules that link to each other, often called cross-linked polymers. They can be used |

|---|

to improve the physical characteristics of a wide variety of materials. In asphalt shingles, they’re added to the asphalt to improve shingle strength and impact resistance.

This doesn’t mean that you’ll see one condition as opposed to the other. It means that conditions during the hailstorm can influence the appearance of hail damage.

Page 72 of 123

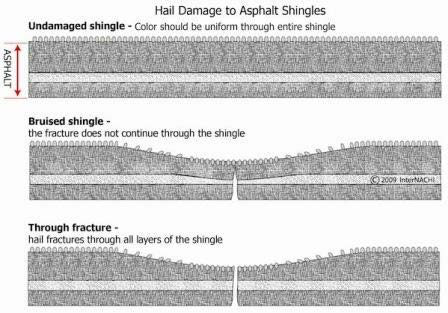

The amount of indentation in the image above has been exaggerated to illustrate the point.

Page 73 of 123

Student Book

Inspecting Asphalt Shingle Roofs

Online Video Course

InterNACHI

Asphalt Composition

Asphalt used for asphalt shingles varies in both quality and thickness, and these two properties can affect the severity of hail damage.

The thickness of the asphalt that is applied to the mat varies among shingles produced by different manufacturers. Obviously, a thicker asphalt layer resists fracture more effectively than a shingle with thinner asphalt of similar properties.

A crack in the asphalt layer does not constitute functional damage. The crack must extend through the mat.

| • |

|---|

We know that UV radiation from sunlight deteriorates exposed asphalt. As a greater amount of asphalt is exposed, the chances of premature failure due to UV-ray deterioration increases. The chances for premature failure are not the same everywhere, but are influenced by:

Page 76 of 123

Student Book

Inspecting Asphalt Shingle Roofs

Online Video Course

InterNACHI

DAMAGE to the GRANULE LAYER

|

|

|---|

Shingles with old or poor-quality asphalt do not hold granules as well as shingles with newer, high-quality asphalt. This means that old shingles are more likely to lose granules when struck by hail. Even small hail can dislodge granules from older shingles. This is especially true when hail is accompanied by heavy rainwater runoff. Heavy runoff can erode loosened granules.

"Hitchhikers"

When shingles are manufactured, in addition to granules embedded into the asphalt, some granules interlock with embedded granules but are not embedded themselves. A lot of these granules come loose during packaging, shipping and installation, but a lot are still attached after installation is completed. These are called “riders” or “hitchhikers.”

Page 79 of 123

The amount of granule loss caused by a hailstrike is affected by the amount of impact-energy carried by the hailstone. The amount of damage done to the granule layer is related to the hail's properties, such as size, density, and free-fall velocity.

Wind-Driven Hail

Page 80 of 123

Student Book

Inspecting Asphalt Shingle Roofs

Online Video Course

InterNACHI

Hailstones that hit shingles with a glancing blow do less damage than hailstones that hit shingles more directly.

Temperature

The best substrate for asphalt shingles is a solid deck. Many manufacturers require a solid deck for their warranty to remain valid. Still, you’ll see many homes with newer asphalt shingles installed over older asphalt shingles, and even over wood shingles or shakes.

Shingles installed over an existing layer of roofing are more likely to suffer hail damage because of poor underlying support. Areas where newer shingles bridge the butts of underlying shingles typically have gaps. These areas will be more easily damaged by hailstones.

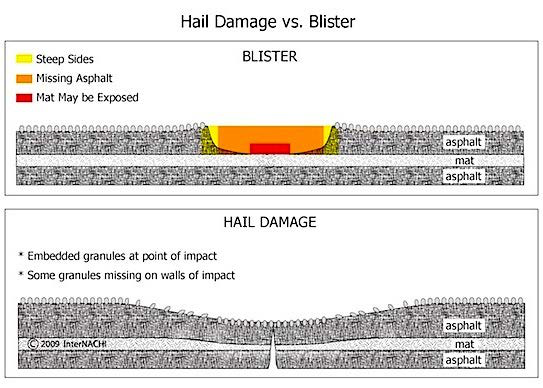

Occasionally, damage from hail is mistaken for damage from blisters.

Page 82 of 123

Student Book

Inspecting Asphalt Shingle Roofs

Online Video Course

InterNACHI

The photo directly above includes a penny for perspective. You can clearly see the steep sides and the exposed mat. Because these shingles are 20 years old, this condition will likely not be covered by the manufacturer’s warranty.

Page 86 of 123

Page 87 of 123

Student Book

When you inspect a home for hail damage, you’ll be looking at components made of a variety of

materials with different properties. These properties affect the severity of hail damage.

• Thicker material resists damage better than thinner material.

• Horizontal surfaces are more likely to be damaged than vertical surfaces because the

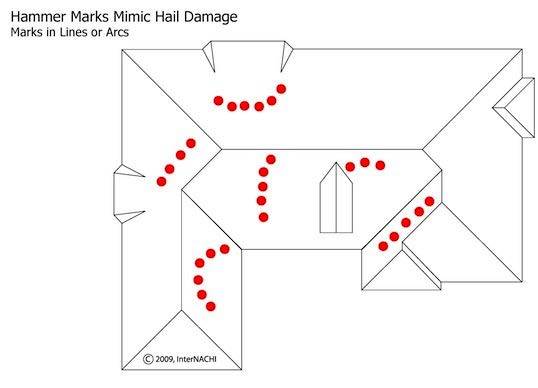

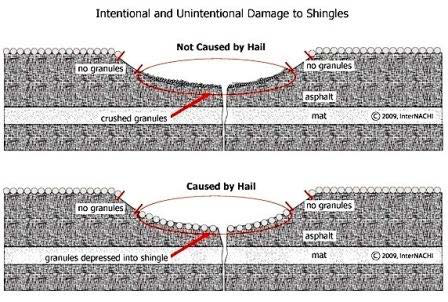

Not all damage that appears to have been caused by hail was actually inflicted by hail. Although it’s not always necessary to identify the source of damage, it’s important that you are able to differentiate between hail damage and damage from other sources.

Although it’s rare, people have been known to use a number of different devices to try to replicate hail damage in an effort to fool insurance companies into paying for a new roof.

Student Book

Inspecting Asphalt Shingle Roofs

Online Video Course

InterNACHI

Page 91 of 123

Student Book

Inspecting Asphalt Shingle Roofs

Online Video Course

InterNACHI

Student Book

Inspecting Asphalt Shingle Roofs

Online Video Course

InterNACHI

The photo above shows two strikes with a ball-peen hammer. The upper strike was made at a 90° angle to the shingle's surface. The granules were pressed further into the asphalt, but not crushed. The lower strike was made with a glancing blow, and you can see that the granules were crushed.

They show the color of the stone, not the color of the coating.

Ball-peen hammers are the hammers of choice for those wanting to mimic hail damage, their advantages being that their heads are spherical, and they're available in the same diameter sizes as common hail.

Hailstone strikes from a single storm often vary quite a bit in appearance.

The photo above shows the uniformity common to ball-peen hammer damage. There’s always the chance that someone will use hammers having different size diameters of balls, but the damage will still be fairly uniform.

Page 96 of 123

The person swinging the hammer almost always over-rotates the hammer to avoid scraping their knuckles against the shingles. This means that the round, flat face of the hammer head doesn’t hit the shingle squarely, but hits with the top edge.

Coins

Page 98 of 123

Page 99 of 123

Student Book

Inspecting Asphalt Shingle Roofs

Online Video Course

InterNACHI

In order to give you an idea of what damage looks like when someone uses a golf ball, we’ve used this golf-ball "whacker" device to damage these shingles. Examined closely, this damage appears similar to a hailstrike. The best evidence that this type of damage is not from hail would be to observe the uniformity and overall pattern of damage across the entire roof.

NON-INTENTIONAL, NON-HAIL DAMAGE

Above is an example of screwdriver damage.

These photos both show mechanical damage. Workmen on a roof often use a variety of tools and equipment. Hand tools, especially when they’re dropped onto a hot roof, can gouge shingles, as will ladders.

Workmen may install equipment that can cause damage if it topples over or is moved accidentally. Common places to find this type of damage are around roof-mounted air conditioners, satellite dishes, and solar-heating and photovoltaic panels.

Studies and actual conditions have shown that asphalt shingles are capable of good performance under conditions of high wind, even though they often don’t perform to their capacity. A large part of the problem is due to improper installation practices.

Based on current knowledge, the most important considerations for preventing wind damage, in order of importance, are:

The UL standard is widely considered to offer better information. According to this standard, shingles are rated as follows:

Failure Modes

Wind damage to shingles generally follows a progression that starts with tab uplift, and can end with shingles being blown off the roof or suffering creased or torn tabs.

The wind force that has the greatest effect on shingles is wind that flows within 2 inches of their upper surfaces. As air flows over a shingle, high air pressure is created beneath the leading edge of the tab. At the same time, air that flows over the top creates an area of low pressure. If these two forces together are greater than the combined strength of the adhesive strip, along with the shingle's weight and stiffness, the result is tab uplift.

Once the edge of a tab is lifted, wind forces on the tab are greatly increased, and uplift then happens quickly because the wind suddenly has more exposed surface to push against.

Shingle Pull-Over

If the shingle pulls over the heads of the lower fasteners, uplift forces on the shingle will increase as the lifting shingle exposes even more surface area upon which the wind can act. Motion this extreme makes it likely that the adhesive strip of the shingle in the course above will be broken.

If the bond of the adhesive strip is broken but the shingle is not pulled over the head of the fastener, the tab may bend far enough to crease or tear.

Blow-Off

In the photo above, you can see a number of creased shingles, indicating that the shingles were not bonded adequately. Where the shingles are missing, you can see in the course below that the shingles were high-nailed, actually with staples. High-nailing shingles drastically reduces the wind resistance of the roof. In this case, wind damage can be expected to continue.

Page 108 of 123

Student Book

Inspecting Asphalt Shingle Roofs

Online Video Course

InterNACHI

• • |

|---|

coatings. In areas and situations in which the available sunlight only marginally warms the roof, highly reflective granule coatings may prevent adhesive strips from bonding adequately.

Transfer

When this happens, a divot may be pulled loose and remain attached to the opposing shingle. This is called transfer because part of one shingle is transferred to another. Both shingles should be replaced.

Inflation

Page 111 of 123

Student Book

Inspecting Asphalt Shingle Roofs

Online Video Course

InterNACHI

TYPES of SHINGLE DAMAGE

Creased or Broken Tabs

Low-quality and older shingles will crease and tear at low wind speeds.

Shingles with adhesive strips contaminated by debris may need to be hand-sealed.

Page 114 of 123

Once the adhesive strips fail, the ability of the shingles to remain in place will rely more on the fasteners. If the wind blows hard enough, it may be able to pull shingles over the heads of fasteners.

Page 115 of 123

Fastener Types

The type of fastener used to fasten the shingles is especially important for resisting wind uplift and pull-through. Fasteners for asphalt shingles should be roofing nails or staples. The head of a roofing nail and the crown of a staple are the parts that actually hold the shingles in place. The minimum width for the staple crown is 15/16-inch.

Student Book

Inspecting Asphalt Shingle Roofs

Online Video Course

InterNACHI

Some shingle manufacturers specify that their shingles be fastened with nails. Nails should be corrosion-resistant, wide-head roofing nails of the proper length. Corrosion-resistant nails can be made of galvanized steel, copper, aluminum or stainless steel.

Proper Fastener Installation

Page 118 of 123

Fasteners should be placed according to the manufacturer’s instructions. Generally, they should be installed below the adhesive strip, equally spaced across the shingle, and placed in slightly from the ends.

Page 120 of 123

This picture shows standard-slope fastening.

The Holding Power of the Substrate

The holding power of the substrate affects the holding power of the fasteners. Decayed or rotten sheathing will not anchor fasteners well.

Fasteners should be long enough to completely penetrate the roof deck. This can be a problem when newer shingles have been installed over old ones, as well as with ridge and hip cap shingles, and with continuous ridge vents.

We’ve come to the end of this training video.