Glass fibre reinforced plastics and othermaterial

| 1 |

|

|

|---|---|---|

Assessment Task: 3

100590084

100590084

Table of Contents

1.4 Background.......................................................................................................................................................1

2 Planning and scheduling site works.......................................................................................................................2

2.3.1 OHS risk at new construction phase..............................................................................................................5

2.4 Construction sequence.......................................................................................................................................5

2.6 Temporary structures and services.....................................................................................................................8

2.6.1 Introduction...................................................................................................................................................8

3.1 Introduction.....................................................................................................................................................12

3.2 Plant and equipment at demolition phase.........................................................................................................12

3.6 Compliance issues for plant with relevant authorities......................................................................................14

3.7 Health and safety of workers with regards to plant and equipment..................................................................15

4.2 Ownership and contract...................................................................................................................................18

4.3 OHS procedures for all site personnel.............................................................................................................19

5 Communication strategies...................................................................................................................................23

5.1 Induction..........................................................................................................................................................23

6 Procedures and strategies to comply with OHS regulations including.................................................................27

6.1 Emergency response........................................................................................................................................27

4.1 Return to work...............................................................................................................................................30

7 Conclusion...........................................................................................................................................................30

Table of figures

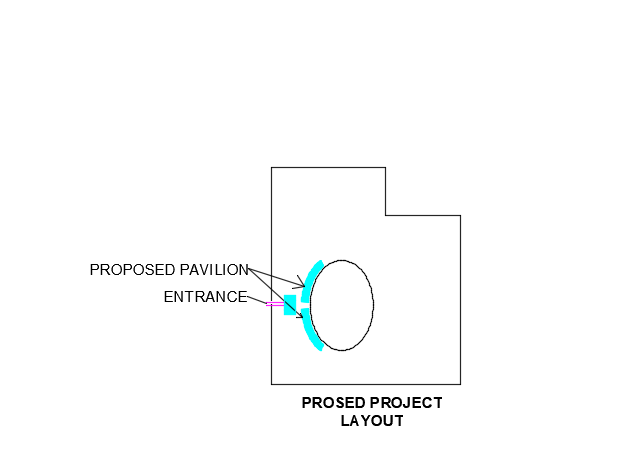

Figure 1 Proposed project layout........................................................................................................................................5 Figure 2 Temporary structures and services......................................................................................................................11 Figure 3 Plant and equipment layout................................................................................................................................14 Figure 4 Bin card format (C.Nikhila, 2008)......................................................................................................................17 Figure 5 Format of material issue requisition (C.Nikhila, 2008)......................................................................................18

1.1 Aim

Understanding of building and construction planning practices

1

1.4 Background

Project sponsor - Cumberland Council

2

Therefore, prior to construction, locations of all the existing service lines should be identified accurately. For the lines which go through the excavation areas, alternative paths should be provided with the approval of corresponding authority. Some authorities relevant to certain services are listed below.

Table 1: Different services and relevant authorities

| Service | Authority |

|---|---|

| Water NSW | |

| Electricity | Energy Australia |

| Gas line |

dig is a nationwide free referral system designed to help to prevent damage and disruption to the large network of Australia’s infrastructure that provide essential services for day to day life.[ CITATION Dia19 \l 1033 ]

2.2 Demolition phase

To ensure public safety, demolition area should be covered with adequate screening. Adjoining roads,

footpaths cannot be interrupted due to demolition process. Overhead protections, heavy-duty

1. Hazard identification

2. Risk assessment

associated with demolition work.

o Also, consulting with site workers about any potential hazards thy know about and checking records of

o Falling objects

General methods of demolition

Powered mobile plants are used in this method and there may be combinations of hand and mechanical

methods. Generally, excavators, bulldozers, cranes and loaders are used. Operator protective structures should

4

Services for the construction

Construction work cannot be carried out without utilities. Prior to begin the construction mainly the power supply and water supply should be obtained for the site. Necessary approvals from authorities should be obtained to have temporary utility connections. All the utilities for the site should comply with all authority requirements.

|

|---|

5

Slips and fall

Noise

2.4 Construction sequence

2.4.1 Method of construction

2.4.2 Procurement items

Procurement is the correct and timely ordering of materials, equipment and supplies to ensure

4. Earthwork

Cutting or filling is done depending on the proposed elevation of the building and the existing ground condition.Foundation work 5.

8. Inclined beam casting and pavilion slab casting

Survey experts are required to ensure that the members are built in the locations as mentioned in the drawings. Post-tensioning is used for the beams. The process is almost similar to the process mentioned in ground beams and ground floor slab construction. Additionally, installation of steel strands and post- tensioning is done.9. Roofing

Cantilever steel frame is design for the roof which should be designed to withstand in severe weather conditions. Corrugated aluminum sheets are used as the roofing material.

Construction delays can be defined as time lag in the completion of construction activities from the specified date. It also includes late starts of activities. Delays affect directly to the specified cost of the project hence reduce the profit margins. Three possible delays for the proposed project and the possible ways of

overcoming can be listed as follows.1. Changes in the design

This can be overcome giving a proper understanding to the client about the project, illustrating with 3D models prior to finalize the project.

3. Unforeseen ground conditions

Temporary structures have to be used to facilitate access, support and protection to the upcoming pavilion construction as well as by ensuring safety for staff and the public. The construction of most elements of the project will require the use of some form of temporary works. Temporary structures will support and protect

8

2.6.2 Temporary structures

Temporary structures have to be utilized in various construction stages in this pavilion construction. They are

Erection works

works

There are two types of scaffolding that can be used in this construction.

- Freestanding scaffolds, such as independent towers

structural elements concreting such as beam concerting, column concreting, slab

concreting, etc.

9

2.6.2.3 Shoring

2.6.2.4 Falsework

Falsework involves a temporary structure used to support other permanent structures until they can support themselves. There are three main types of systems can use as falsework in this construction. These include:

There are different reasons for dewatering this pavilion foundation excavation such as keeping the excavation dry, preventing ground water or soil leaking, preventing sand boiling, preventing bobbling, preventing floating in the basement.

Dewatering can be carried out by a number of methods from open excavations or trenches. However, the easiest thing is to use the drainage channels to work water down to the point of discharge, which carries water from the site.

2.6.3 Temporary services

It is important to maintain and operate temporary services to ensure continuous construction and service.

Sanitary Facilities

Provision and maintenance of sanitation services will provide for individuals on the workplace that compliance with state and local health regulations. Toilets will locate near the work site and secluded from view insofar as possible. Toilets have to clean and supplied throughout the construction work.2.6.3.2 Field office

location for materials and equipment susceptible to weather damage.

2.7 Plan of temporary structures and services

3.1 Introduction

Machines are essential for the accomplishment of the project within specified time frame. Plant and

equipment for demolition are listed below.

Table 2 Plant and equipment for demolition

| 3.3 | | |

|---|---|---|

| | ||

| |

|

|

| |

|

|

| | ||

| | ||

| | ||

Table 3 Plant and equipment for new construction phase

|

|

|---|

When considering the chosen plant and equipment, there will be some restriction for the access unless planned properly.

When establishing the tower crane, its total range should cover the site with minimum interruptions to adjoining properties.