Mobility and access casting sequence overhead obstructions

CPCCBC4011B: Assessment 4

|

|---|

Please type your answers in black font. (Calibri 12 point)

It is recommended that you are familiar with the following resources and standards prior to completing this assessment:

o Learning Resources for CPCCBC4011B

o NCC Vol 1

o AS1170.1 Structural design actions – Permanent, imposed and other actions

o AS1170.2 Structural design actions – Wind actions

o AS3850.2 Prefabricated concrete elements – Building Construction o National Code of Practice for Precast, Tilt-up and Concrete Elements in Building Construction

o AS3600 Concrete structures

o AS4100 Steel structures

o Code of Practice: Demolition Work

o AS2601 The Demolition of structures

You may make any assumptions you need to, but be sure to include them as part of your submission.

| 1. | |

|

|

|

LA023654, Assessment 4, CPCCBC4011B, Edition number 4 |

•The second, the design for erection, is for the handling, transportation and erection of the individual elements and structure during the

|

3 |

|---|

A:

Planning and erection:

•site limitations

•local street access

•element sizes

•crane size, mobility and access

•casting sequence

•overhead obstructions, including overhead power lines

|

LA023654, Assessment 4, CPCCBC4011B, Edition number 4 |

|---|

A:

1.Drawing number

2.Project name and location

3.Scale and drawn/checked/verified details

4.Sign-off box for the “Approving Engineer”

5.Element number and weight

6.Number of elements to be cast

7.Element dimensions and centre of gravity

8.Concrete grade and cover to reinforcing

9.Surface finish to all surfaces

10.Position and size of all reinforcement

11.Location and product specification of all cast-in fittings (eg. for lifting bracing & connections / fixings)

12.Any special handling or storage requirements, e.g. strong backs 13.Quality assurance checks.

c) steps to be taken prior to commencing erection, and A:

|

5 |

|---|

A:

•Ensure appropriate lifting equipment is used, which should be referenced in the shop drawing.•Maintain communication between the crane operator and the dogger to help ensure that the crane does not move away prior to the lifting equipment being disconnected from the panel.

A: The parties involved include

•Designer who may be the Architect or the Structural •Engineer or the Façade Engineer

•Proprietor or Client

|

LA023654, Assessment 4, CPCCBC4011B, Edition number 4 |

|---|

|

|---|

A:

Choosing Dincel polymer formwork:

Dincel Structural Walling is an internationally patented permanent polymer formwork for walls and columns, which when filled with ready mixed concrete, produces an economical, strong, durable structure. It is one permanent formwork option available in Australia that claims to be a fast, cheap, and easy alternative to block/brickwork and precast and in situ concrete building methods.

Its fire ratings, combustibility, waterproofing, earthquakes, acoustics, toxicity and VOC testing. are certified BEP Approved (Best Environmental Practice) on the use of PVC recycled material during manufacturing and end of life management for sustainable buildings in construction.

FRL (Fire Resistance Level)

The formwork material is comprised of certain additives which enhances fire performance. In the event of a fire, the material safely chars and intumesces. The solid concrete within provides the necessary fire rating. Warringtonfire and CSIRO have confirmed that the polymer webs do not melt away or negatively affect the concrete wall’s performance for FRL. As such, in accordance with AS 3600, a Dincel wall can achieve up to 90/90/90 for 110mm up to 240/240/240 for 275mm.•Finishing a polymer based permanent formwork wall can mean rethinking your waterproofing, adhesives and coatings, cladding materials and methods.

Note to students: include brief but relevant and significant aspects, not irrelevant detail.

or

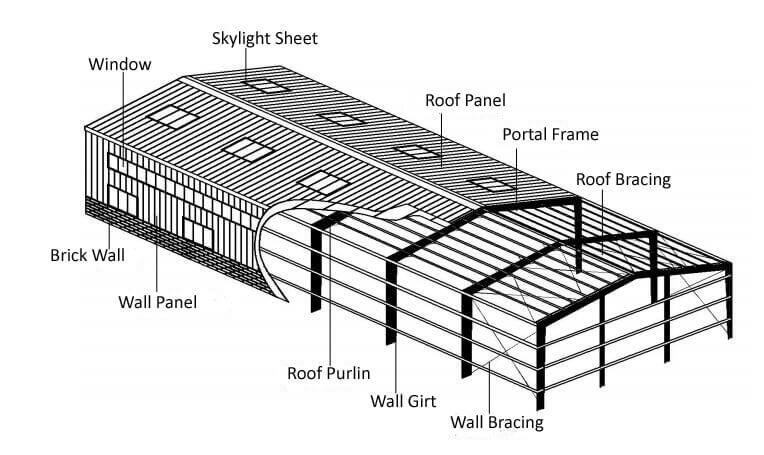

Task 2 – Roof systems

© New South Wales Technical and Further Education Commission, 2020 (TAFE NSW), Version 2, September 2020

|

||

|---|---|---|

| LA023654, Assessment 4, CPCCBC4011B, Edition number 4 | ||

© New South Wales Technical and Further Education Commission, 2020 (TAFE NSW), Version 2, September 2020

a. Label or provide brief descriptions of all images.

| 11 |

|---|

|

|

|---|

| 2. |

|---|

© New South Wales Technical and Further Education Commission, 2020 (TAFE NSW), Version 2, September 2020

| 3. |

|---|

A:

Load path extends from the roof through each structural element to the foundation. The load path can be identified by considering the elements in the building that contribute to resisting the load and by observing how they transmit the load to the next clement. Depending on the type of load to be transferred, there are two basic load paths:

•gravity load path

•lateral load path

Both the gravity and lateral load paths utilize a combination of horizontal and vertical structural components and explained as:

© New South Wales Technical and Further Education Commission, 2020 (TAFE NSW), Version 2, September 2020

Execution Standards: AS/NZS 5131 Structural steelwork

c. prepare an Inspection & Test Plan for ensuring the compliance of the roof construction with project documentation.A:

| Inspection and Test Plan for Steel Structure | ||||||||

|---|---|---|---|---|---|---|---|---|

|

|

|||||||

| Manuf. | Client | |||||||

|

|

|||||||

| BeforeManufacturing | ||||||||

|

|

|

||||||

|

|

|

||||||

|

|

|||||||

| 19 |

|---|

© New South Wales Technical and Further Education Commission, 2020 (TAFE NSW), Version 2, September 2020

H: Hold Point = Hold on the production till TPI Inspector performs inspection and supervise the required test

W: Witness Point = Manufacture shall notify client and TPI Inspector but there is no hold on the production;

Client can waive this inspection based on his discretion and informs TPI Inspector accordingly.R: Document Review = Review means Review document, which includes of material test certificates, WPS, PQR, NDT Procedures and etc.

_______________________________

_______________________________