Operations and supply chain management

JOHN GRABARCZYK

• Six Standard deviations between the mean and nearest specification limit in a process

• Belts: Black, Black Master, Green, Yellow & White

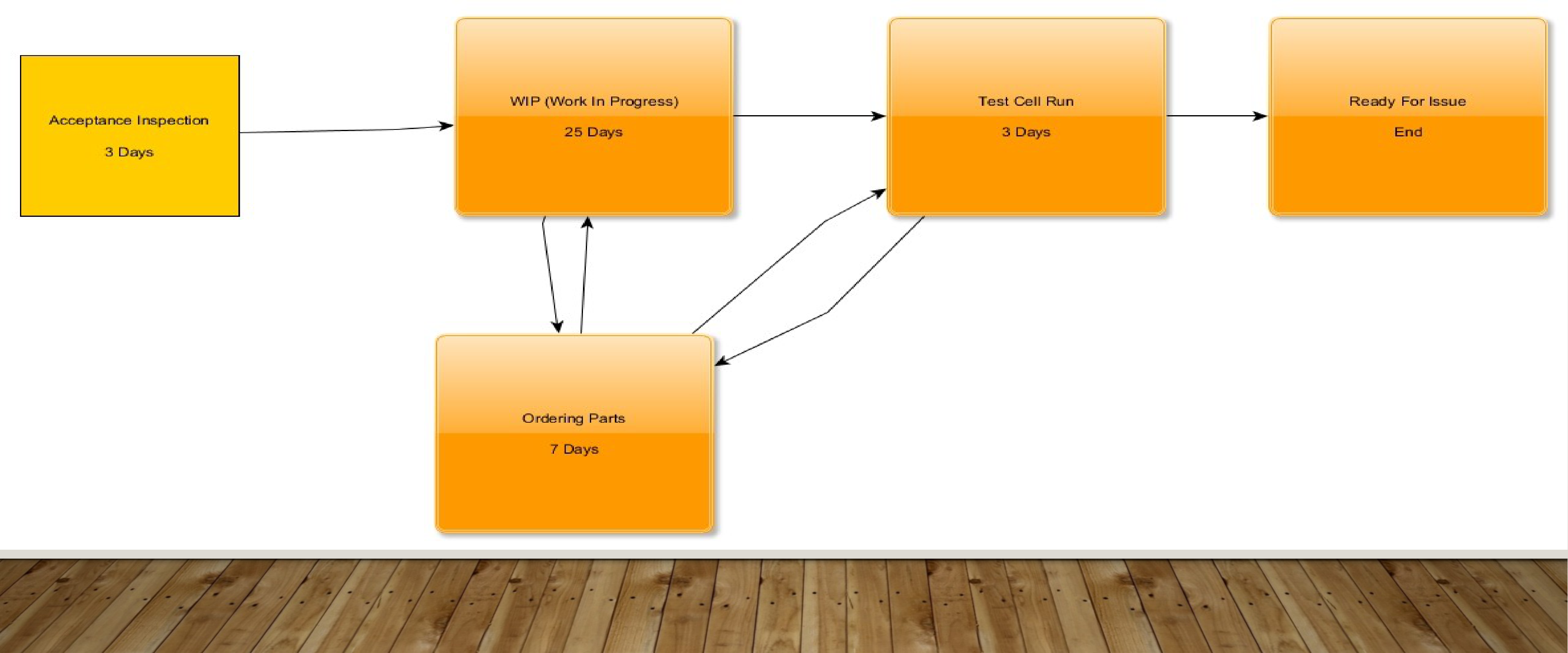

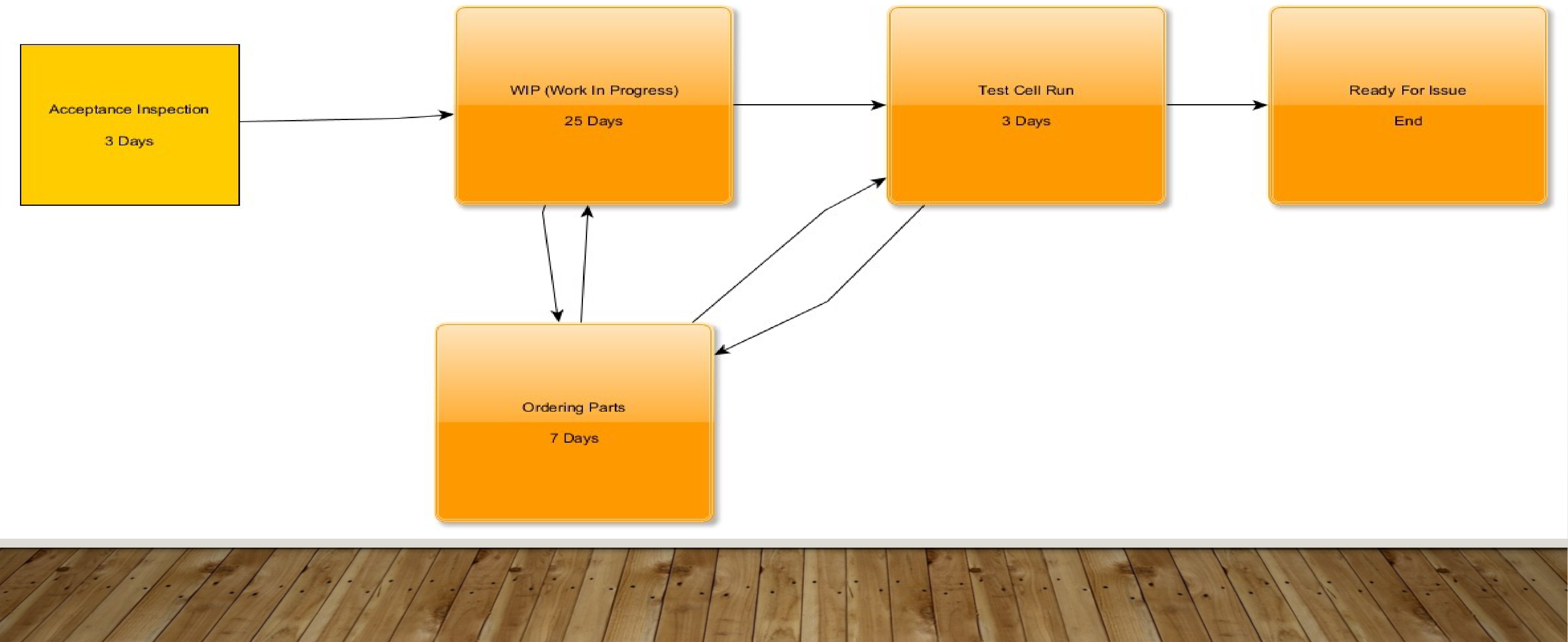

Current Process

• Through time-reduction, more engines should be placed in an RFI status than before

• Business Objectives

• Time for parts to arrive also needs to be reduced to allow for proper

maintenance to occur• Customer needs and Feedback

Current Process

CTQs

Descriptive statistics of The Proposed Process

Forecasted Inventory/Pull System Accept/ Inspection Work in Process/WC Test Cell Run Total Maint/ Days

minimum 2 22 2 26

maximum 3 25 3 30

confidence interval 95.% lower 2.22 22.67 2.19 27.37

confidence interval 95.% upper 2.58 23.53 2.54 28.36

coefficient of variation (CV) 20.76% 5.25% 20.71% 4.96%

1st quartile 2.00 22.00 2.00 27.00

Internal Processes Influencing CTQs

Internal processes influencing CTQs

• Determine the Basic Requirement of the Customer• Identify the First level of Requirements of

Customers

• Identify the Customer’s Second Tier of

Requirements

• Bring to an end when the Quantifiable

Requirements Reaches the limit

• Confirm Final Requirements with the Customers

• How will success be measured in the future?