Size the vessels the two separators and the teg tower

|

||

|---|---|---|

|

||

|

||

Dynamic simulation specification

| Liquid Level (%) | 50 | 50 |

|---|

Cooler: ∆P = 5 psi, Tout = 80 ◦F, V = 530 ft3.

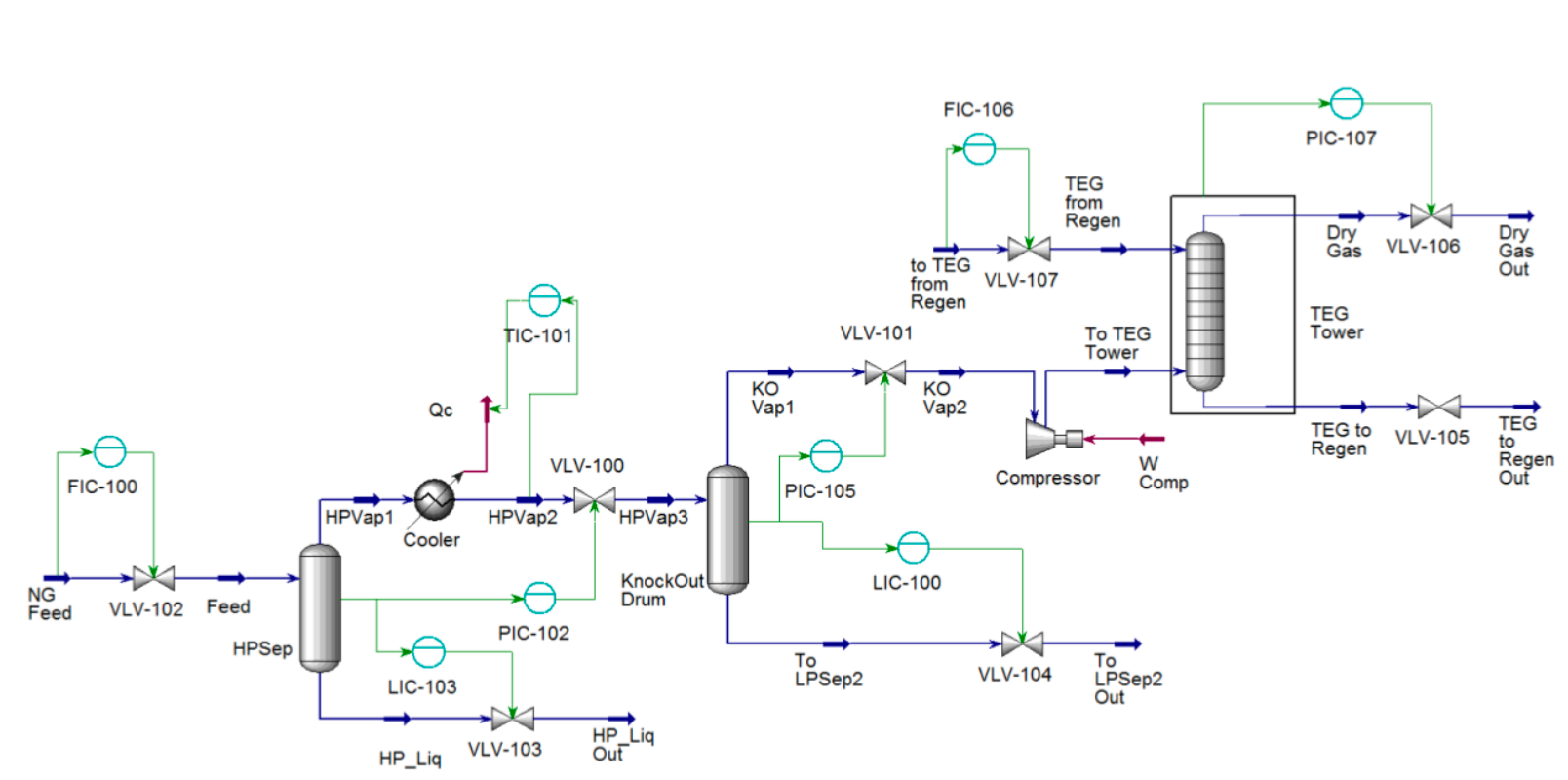

(a) Simulate this process in Hysys using the specifications given. Adjust the TEG from Regen flow rate such that the mole fraction of water in the Dry Gas stream is 0.0001 (set a tolerance of 5E-5 for the target value). This is your steady-state “base case”. Report the mass flow rate of TEG from Regen stream and the temperatures, pressures, molar flow rates and molar compositions of the four product streams (HP_Liq, To LPSep2, Dry Gas, and TEG to Regen).

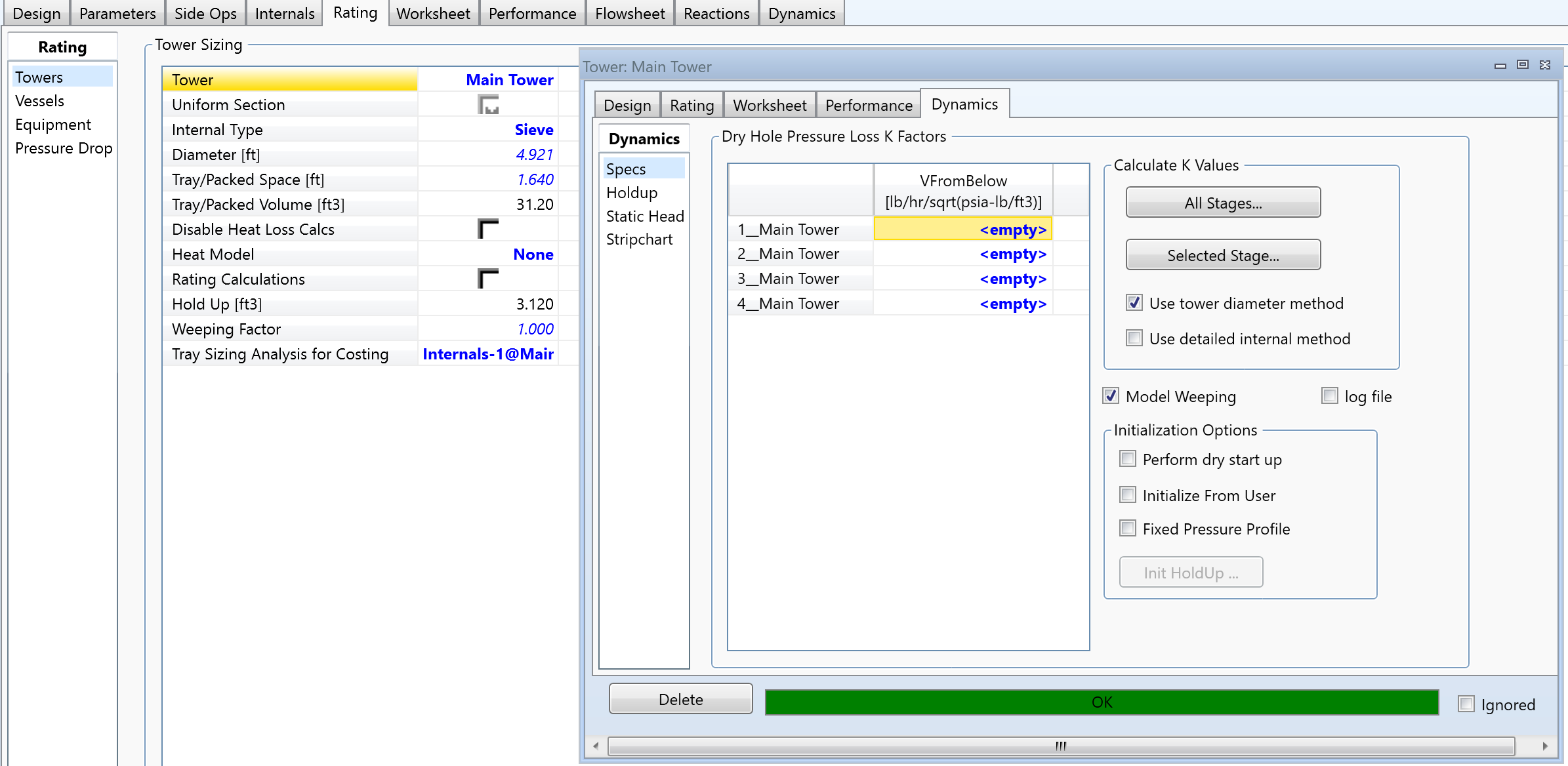

(b) Run the simulation in the dynamic mode in Hysys. Before switching to dynamics, size the vessels (the two separators and the TEG tower). To size the separators, use “Quick size” (see Figure 2). Report the vessel sizing results. For the two separators, compare the resulting volumes with those estimated using the heuristics learned in class and use the more conservative estimate in your simulation.

Figure 3: Sizing TEG Tower

Figure 4: Natural gas processing plant, dynamic simulation

4

Appendix—Definition of Hypocomponents

4.Click the New Hypo button five times to add five hypothetical components.

5.Use the following table to add Name, NBP and Liq Density information:

6.Select the Estimate Unknown Props button to estimate all of the unknown properties and close the window.

7.Click the Add All button to add the hypocomponents to the component list.