Spie electroactive polymer actuators and devices

Proceedings of the ASME 2019 Conference on Smart Materials, Adaptive Structures, and Intelligent Systems

SMASIS 2019

September 9-11, 2019, Louisville, KY, USA

SMASIS2019-5587

| David Bombara | Vasilii Mansurov | Revanth Konda |

|---|---|---|

| Smart Robotics Laboratory | ||

| Department of Mechanical Engineering | Department of Mechanical Engineering | Department of Mechanical Engineering |

| University of Nevada, Reno | University of Nevada, Reno | University of Nevada, Reno |

| Reno, Nevada 89557 | Reno, Nevada 89557 | Reno, Nevada 89557 |

| Email: dbombara@nevada.unr.edu | Email: vmansurov@nevada.unr.edu |

Steven Fowzer

Smart Robotics Laboratory

Department of Mechanical Engineering University of Nevada, Reno

Reno, Nevada 89557

Email: sfowzer2@nevada.unr.eduABSTRACT

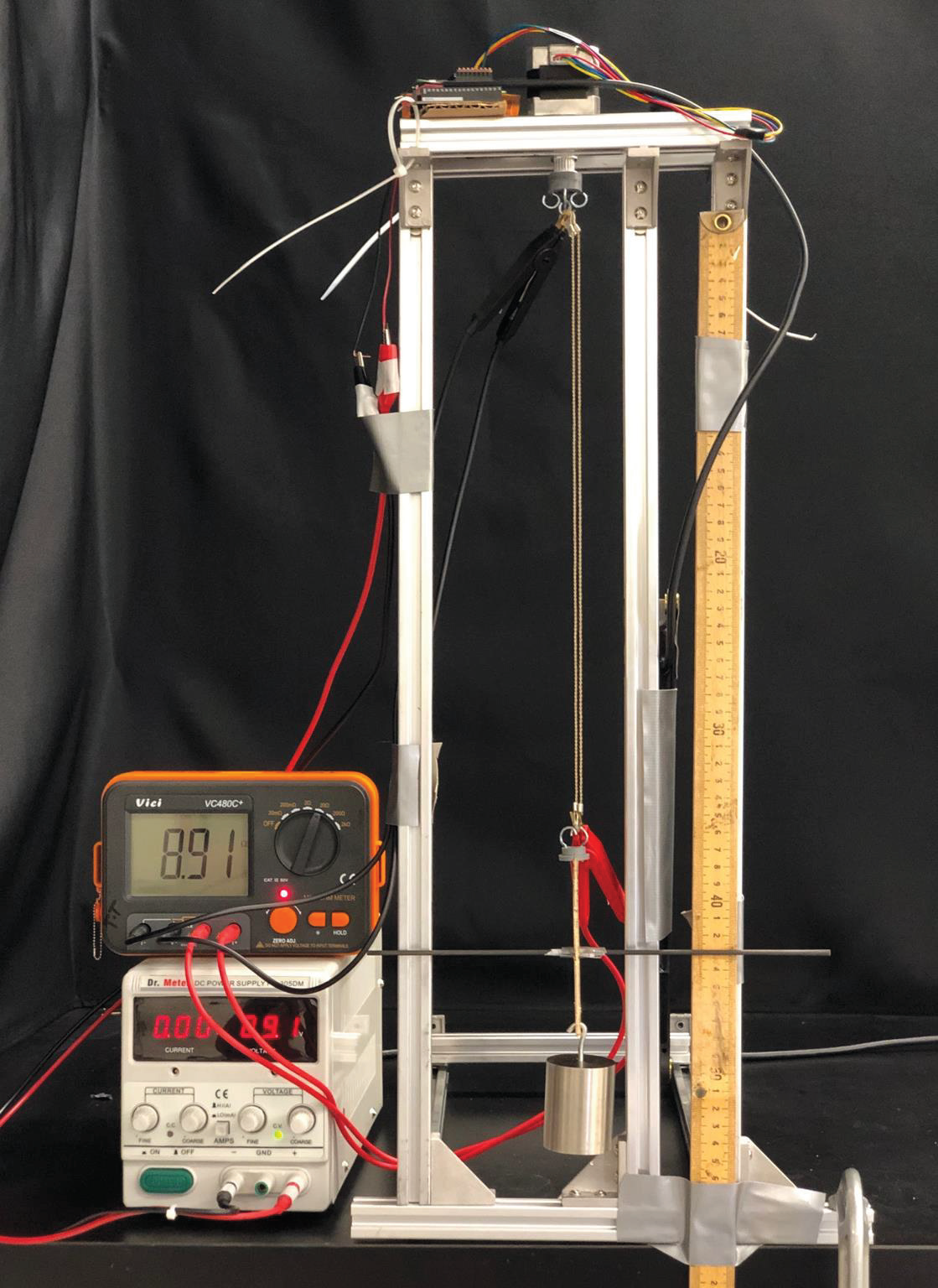

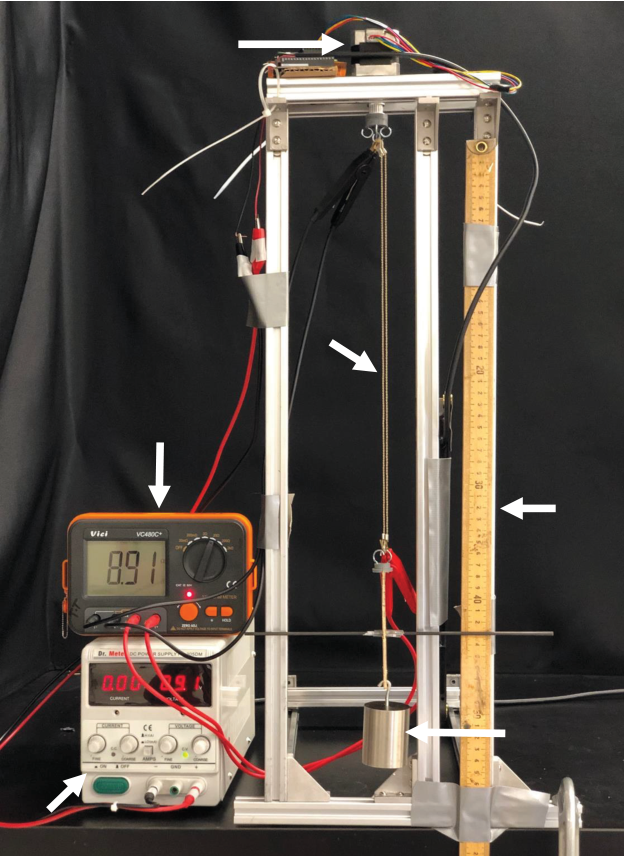

The twisted string actuator (TSA), as a recently discovered artificial muscle, has attracted a lot of attention as a compli-ant and powerful actuation mechanism. A TSA consists of two strings attached to a motor on one end and a load on the other end. The motor’s rotation twists the strings and generates linear actuation. A common challenge is to obtain TSAs’ strains using compact approaches. Previous studies exclusively utilized ex-ternal position sensors that not only increased system cost, size and complexity, but also lowered actuator compliance. In this paper, self-sensing strategies are presented to estimate TSAs’strains without external sensors. By incorporating conductive and stretchable nylon strings, called super-coiled polymer (SCP) strings, into TSAs, their strains can be estimated from the resis-tance values of SCP strings. Two self-sensing configurations are realized: (1) TSA with one regular string and one SCP string, and (2) TSA with two SCP strings. Experiments are conducted to show the correlation between the length and resistance of TSA

FIGURE 1. The schematic of a twisted string actuator (TSA) (left). A |

|---|

Although TSAs are strong, compliant, and compact, a com-mon challenge is to obtain the contraction of TSAs using com-pact solutions. One approach is through accurate modeling of TSAs. Models that relate the strings’ rotations to their change in length have been developed [14, 19]. However, the correla-tion may change significantly depending on the externally ap-plied load [14]. To know the displacement, one must also know the load applied to the strings. Another common approach is to

utilize external position sensors – the adoption of external sen-sors not only increase system cost, size and complexity, but also lower actuator compliance which is undesirable for applications like soft robots, robot exoskeletons, and medical assistive de-vices.

2 Copyright © 2019 by ASME

of SCP strings. Two self-sensing configurations are realized: (1) TSA with one regular string and one SCP string, and (2) TSA with two SCP strings. A series of experiments are conducted to show the correlation between the length and resistance of TSA under different conditions. Polynomial and Preisach hysteresis models were successfully employed to capture the Length – Re-sistance correlation and to estimate TSA’s length using the re-sistance. Furthermore, the advantages and disadvantages of the approaches are discussed.

PROPOSED SELF-SENSING SCHEMES

| Motor |

|

|||

|---|---|---|---|---|

| Multimeter | ||||

|

||||

|

||||

| mate the length of the TSA using its resistance value: | ||||

| Llinear(R) = p0 + p1R+ p2R2+···+ pkRK, | (1) | |||

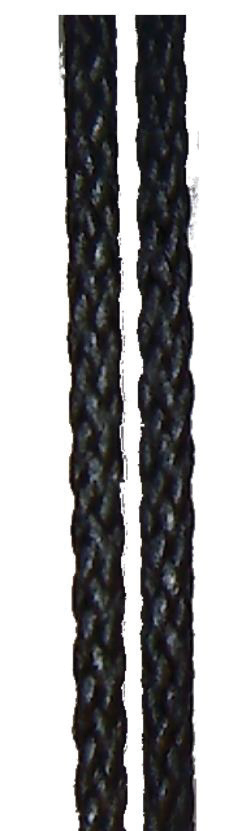

second step, the coiled thread was double backed on to form a stable structure. Sample SCP strings are shown in Figure 2. It’s noted that heat treatment is commonly required to fabricate SCP strings as actuators. In this study, it’s found that heat treatment had negligible effect on their use as sensors, so heat treatment was eliminated from the fabrication process.

By coiling a different number of nylon threads, SCP strings with different diameters can be manufactured. In this study, two types of SCP strings were fabricated with different thicknesses, one manufactured by using 4-ply nylon threads (referred to as“Thin SCP String”), and the other with 8-ply nylon threads (re-ferred to as “Thick SCP String”). The number of turns and weights used for the coiling process were determined experimen-tally. More details about the manufacturing of SCP actuators can be found in [11] and [26].

The average absolute error and standard deviation were em-ployed to evaluate the modeling performance:

Scheme 1: TSA with One Regular String and One SCP

String

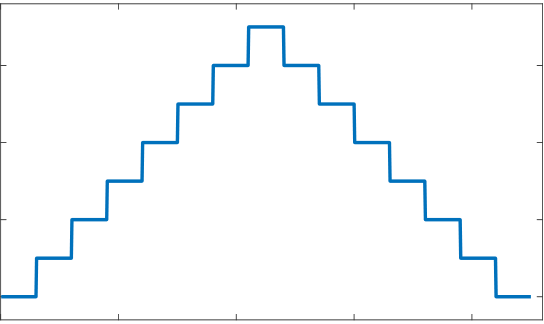

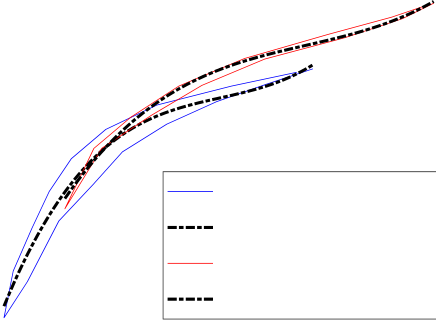

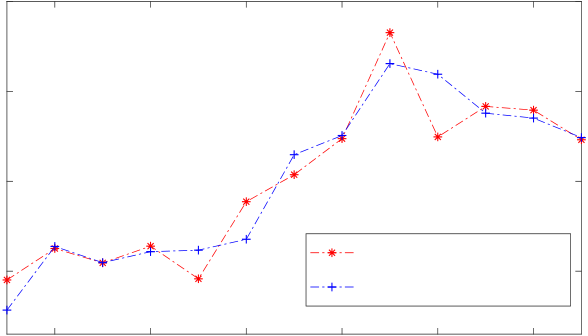

Case 1: Thin SCP String Experiments were conducted to

measure the relationship between the length and resistance of the TSA

whose SCP string was made with 4-ply nylon threads. A sequence of

rotations ranged from [20, 55] were used, as shown in Figure 4(a). This

sequence was adopted since it con-sisted of both twisting and untwisting

cycles. The steady-state length and resistance values were measured. As

shown in Fig-ure 4(b), by twisting the TSA, its length decreased from 28

cm

5 Copyright © 2019 by ASME

| 50 |  |

Length (cm) | 450g | Resistance ( ) |

|

|||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

550g | |||||||||||||||||||||||||||

| 40 | ||||||||||||||||||||||||||||

| 30 |

|

|

||||||||||||||||||||||||||

| 20 | ||||||||||||||||||||||||||||

| 0 | 10 | 20 | 30 | 40 | 20 | 30 | 40 | 50 | 22 | 24 | 26 | 28 | ||||||||||||||||

| Time (min) | Number of Turns | Length (cm) | ||||||||||||||||||||||||||

| (a) | (b) | (c) | ||||||||||||||||||||||||||

| Length (cm) | 28 | Length (cm) | 28 | Modeling error (cm) |

|

15 | ||||||||||||||||||||||

| 26 | 26 | |||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||

| 24 | 24 |

|

||||||||||||||||||||||||||

| 0 | ||||||||||||||||||||||||||||

| 22 | 22 | 5 | ||||||||||||||||||||||||||

| 22 | 24 | 26 | 22 | 24 | 26 |

|

||||||||||||||||||||||

| Resistance ( ) | Resistance ( ) | Index | ||||||||||||||||||||||||||

| (d) | (e) | (f) | ||||||||||||||||||||||||||

| FIGURE 4. |

|

|||||||||||||||||||||||||||

6 Copyright © 2019 by ASME

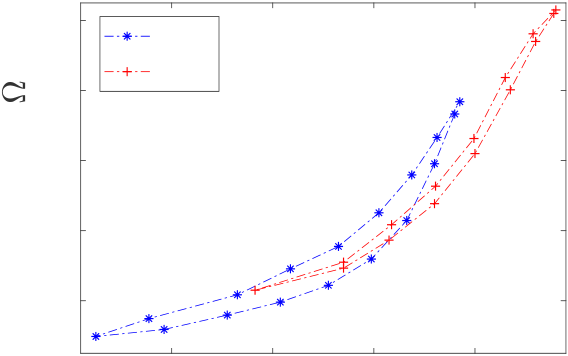

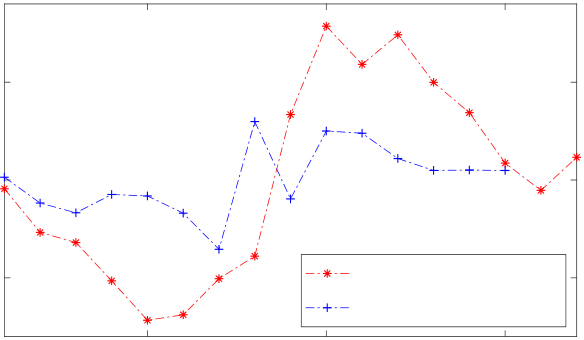

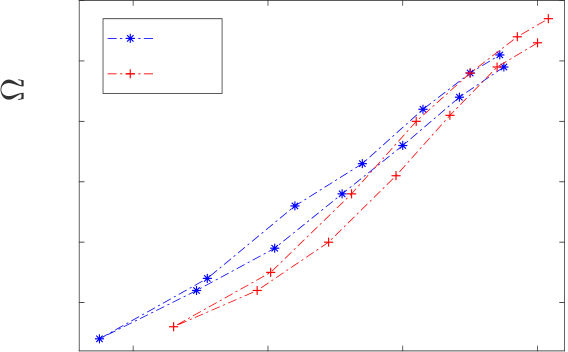

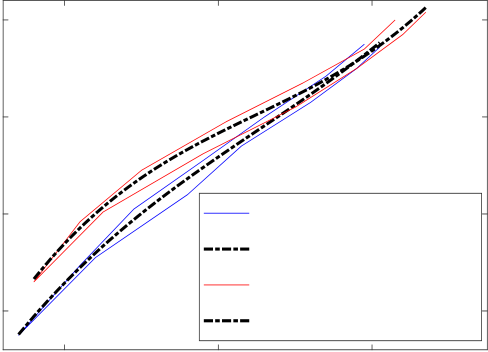

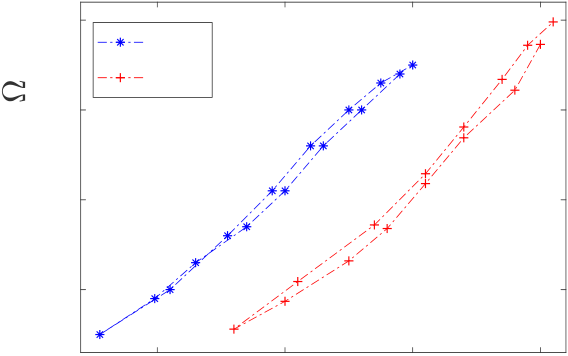

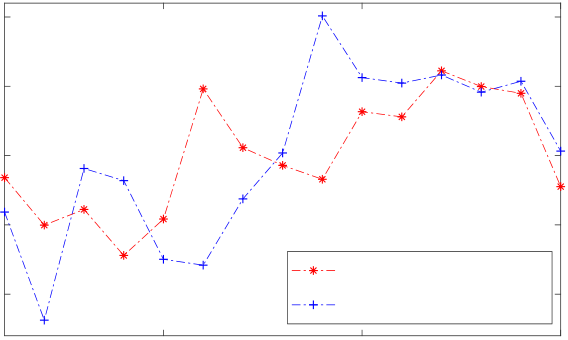

over 6 cm of length change was demonstrated, while the Scheme 2, the actuation range of the TSA was 2-3 cm, as shown in Fig-ure 4(c) and Figure 5 (a), (d), and (g). In other words, the mod-eling error of the third-order polynomials is greater for scheme 1, but that configuration also demonstrates a greater contraction range. For Scheme 2, however, the opposite was observed. Mod-eling error was less than Scheme 1, but so was the contraction range. Compared to Scheme 2, Scheme 1 can withstand bigger loads due to higher tensile strength of the polyethylene string. For practical purposes, one may choose a balance between con-traction range, modeling error, and load capacity.

For all the presented experimental results, the resistance of TSA increases with a larger length. Therefore, greater loading conditions generally increase the resistance in SCP strings. The change in resistance in Schemes 1 and 2 can be credited to the increase in the magnitude of tension exerted on the SCPs due to the twisting. The other cause for this phenomenon specifically in Scheme 2, is the increase in the surface area of contact between the SCP strings as a result of twisting, which would lead to an increase in conductivity and consequently decrease in resistance.

Modeling and control”. In Proc. IEEE/ASME Int. Conf. Adv. Intell. Mech., pp. 1215–1220.

[14] Palli, G., Natale, C., May, C., Melchiorri, C., and Wurtz, T., 2013. “Modeling and control of the twisted string actuation system”. IEEE/ASME Trans. Mech., 18(2), pp. 664–673.

[18] Gaponov, I., Popov, D., Lee, S. J., and Ryu, J.-H., 2017.

“Auxilio: A portable cable-driven exosuit for upper extrem-ity assistance”. Int. J. Control Autom. Syst., 15(1), pp. 73–84.

[22] Madden, J. D. W., and Kianzad, S., 2015. “Twisted lines: Artificial muscle and advanced instruments can be formed from nylon threads and fabric.”. IEEE Pulse, 6(1), pp. 32–35.

[23] Padgett, M. E., and Mascaro, S. A., 2019. “Investigation of manufacturing parameters for copper-wound super-coiled polymer actuators”. In Proc. SPIE: Electroactive Polymer Actuators and Devices, Vol. 10966.

9 Copyright © 2019 by ASME

2 mm

2 mm