The time control unit used vary the output quantity water

CHAPTER: - 1

INTRODUCTION

A device which transfer fluids (gases or liquids), or sometimes mechanical actions slurries is known as pump. According to their methods of moving fluids, there are three types of pumps which can be classified in major types: gravity pumps, direct displacement, lift. Pumps are operated to perform work by transferring the fluids by consume energy using reciprocating mechanisms. Manual operation, engines, wind power or electricity are the energies can be used to operate the pumps. Broad range of mechanical pumps are used in the industry applications such as aquarium filtering water pumping, wells, pond filtering, for water cooling and fuel injection in automobile industry, for pumping oil and natural gas in energy industry.

The Pump can be classified into two types as follows:

Positive Displacement Pump (PDP):

Non -Positive Displacement Pump (NPDP)

GOALS AND MOTIVATION

Primary objective of the invention is to provide water or oil pumped of the higher pressure, it has higher efficiency, compact in size, less maintenance and it is very economical as we can use air to pump the water.

DESCRIPTION

Initially starting with the air compressor, it is used to pressurize the air by compressing it from atmospheric low pressure to high pressure. It can be achieved by decreasing air volume. Compressor is mostly positive displacement unit and can be reciprocated piston type or the rotary types. Small sized compressor is used, which consists of 2 stage compressor unit. An electric rotor, pulley drive, compressed air tank, instruments and pressure controls are parts comprised in the compressor for quick hook up and use. 10 HP motor is used to drive the compressor and operating design are in the range of 145-175 PSI. In the event, if the pressure goes above the receiver designed pressure, release valve is provided which releases excess pressure to atmosphere and therefore odds of any risk to occur is diminished.

WORKING PRINCIPLE:

The piston stroke length can be varied by taking appropriate timer adjustment.

COMPONENTS:

Pneumatic Cylinder

Connectors

Base

Pneumatic Cylinders

Fig.1.2 Pneumatic Cylinders

Single Acting Cylinder

Cylinder which is equipped for playing working medium in a single heading is known as single acting chamber. It is outfitted with one channel for the working weight, which can be created in various fundamental various plans. Power is created one way as it were. In this way, control hardware which is overwhelming ought to not be connected to them. For return stir, single activity Cylinder requires simply after portion of the air volume.

Double Acting Cylinder

Hydraulic Cylinder

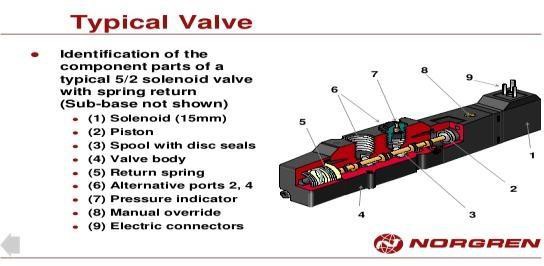

SOLENOID VALVE

One of the significant pieces of a pneumatic framework is the course valve. To control the course of wind current in the pneumatic framework is normally known as DCV. The position of its internal movable parts is changed by the directional valve. To operate quickly, to reduce the manual human effort and to modify the machine to operate automatically with the help of solenoid valve. An electrical device which converts straight line motion from electrical energy and force is known as solenoid. To operate mechanical operation which results in operating the valve, mechanism, solenoids are used. Type of solenoid may be push or pull. When the solenoid is energized electrically then the plunger is pushed, it’s called push type solenoid. The plunger is pulled when the solenoid is charged is called pull solenoid. The parts of solenoid should be remembered to recognize the parts which is faulty.

Coil (Electromagnetic):

Frame

The mover instrument of the solenoid will be solenoid plunger. Steel overlays are utilized to made plunger; these are bolted together and fixed under high weight at that point there will be no development of the cover as for one another. Stick gap is put on the highest point of the plunger. Movement of plunger is carried by a one directional magnetic force and with spring action it returns to the original position. Covers are provided by solenoid operated valves over either the entire valve or the solenoid. Covering of solenoid shields the solenoid from earth and other remote issue, and secures the actuator.

NRV - Non-Return Valve

Valve which permits liquid (fluid or gas) to course through it in just a single bearing is known as non-return valve. Two-port valves are provided in the check valves which means one valve for fluid to enter and other valve to leave the fluid. Several types of check valves are used in an extensive variety of applications in the valves. For common household items, check valves are often used. They are available in a broad range of sizes and costs. Check valves are typically very simple, small, or inexpensive check valves which work robotically and most of them are not managed by means of a individual or any external manipulate. Plastics or metals are used to made the bodies of most check valves.

Flexible Hoses

Connectors

Two types of connectors are used in this system viz. hose connectors and reducer. An adoptee hose nipple and cap nut are consisting in the hose connectors. Brass or aluminum or hardened pneumatic steel are being used to made these types of connectors.

Base

ADVANTAGES:

Advantages of Hydraulics

Maximum power transmission is possible because the supplied energy does not absorb by oil. Due to incompressibility, high loads and forces can be resisted. The hydraulic fluid is incompressible, which results for minimum of vibrations.

Advantages of Project

More advantages of pneumatic water pump than the pumps which are similar in size.

Efficiency is high

Positive displacement pump is fully efficient

LIMITATIONS

When compared to other device, efficiency is less.

Working of unit is affected by the leakage of air.

APPLICATIONS

LITERATURE REVEIW

The word ‘pneumatic’ originates from Greek and means breather wind. The phenomena and study of air movement is known as pneumatic. To carry out the simplest mechanical tasks, pneumatics is used when time permits. Recently in automation technology, development of pneumatic technology has important role. To suit the capacity of system, it works on compressed air supply which should available in adequate quantity with pressure. At the point when the pneumatic systems are being embraced just because, anyway it wills without a doubt the vital arrangement with subjected to compressed air supply. The key piece of any facility of compressed air supply is by methods utilizing reciprocating compressor. The machine which takes air at some low inlet pressure and converts it at high pressure is known as compressor.