Too reduce lead time when the lead time long

· Introduce common inventory control systems designed to reduce costs

· Identify inventory reduction strategies including just-in-time inventory management

· Firms need to hire people to take care of inventory

· The goal in inventory management is to minimise inventory holding while maintaining a desired customer service level.

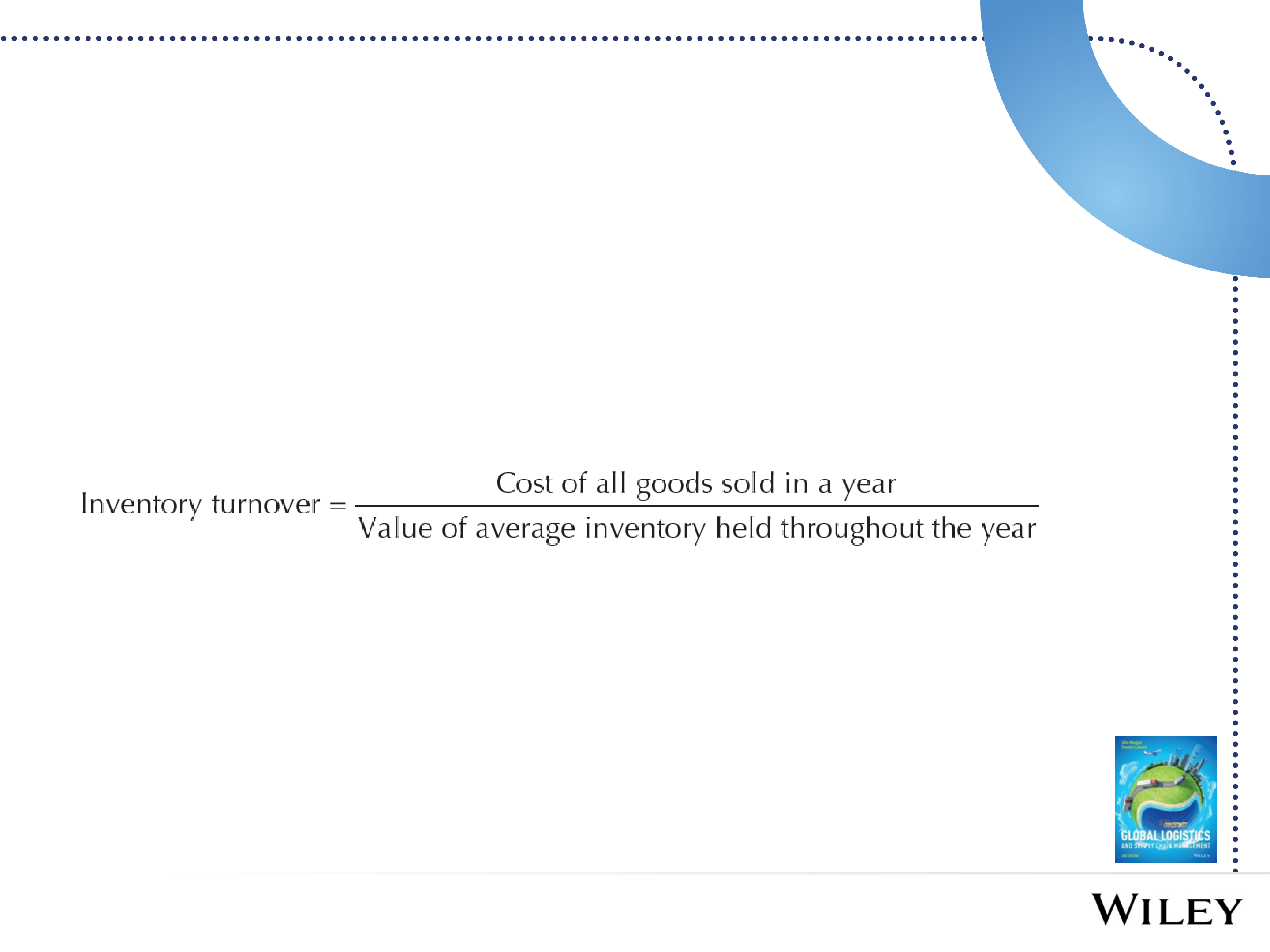

– The higher the turnover, the lower the firm’s inventory costs

Inventory turnover

– SS: Safety Stock, in units

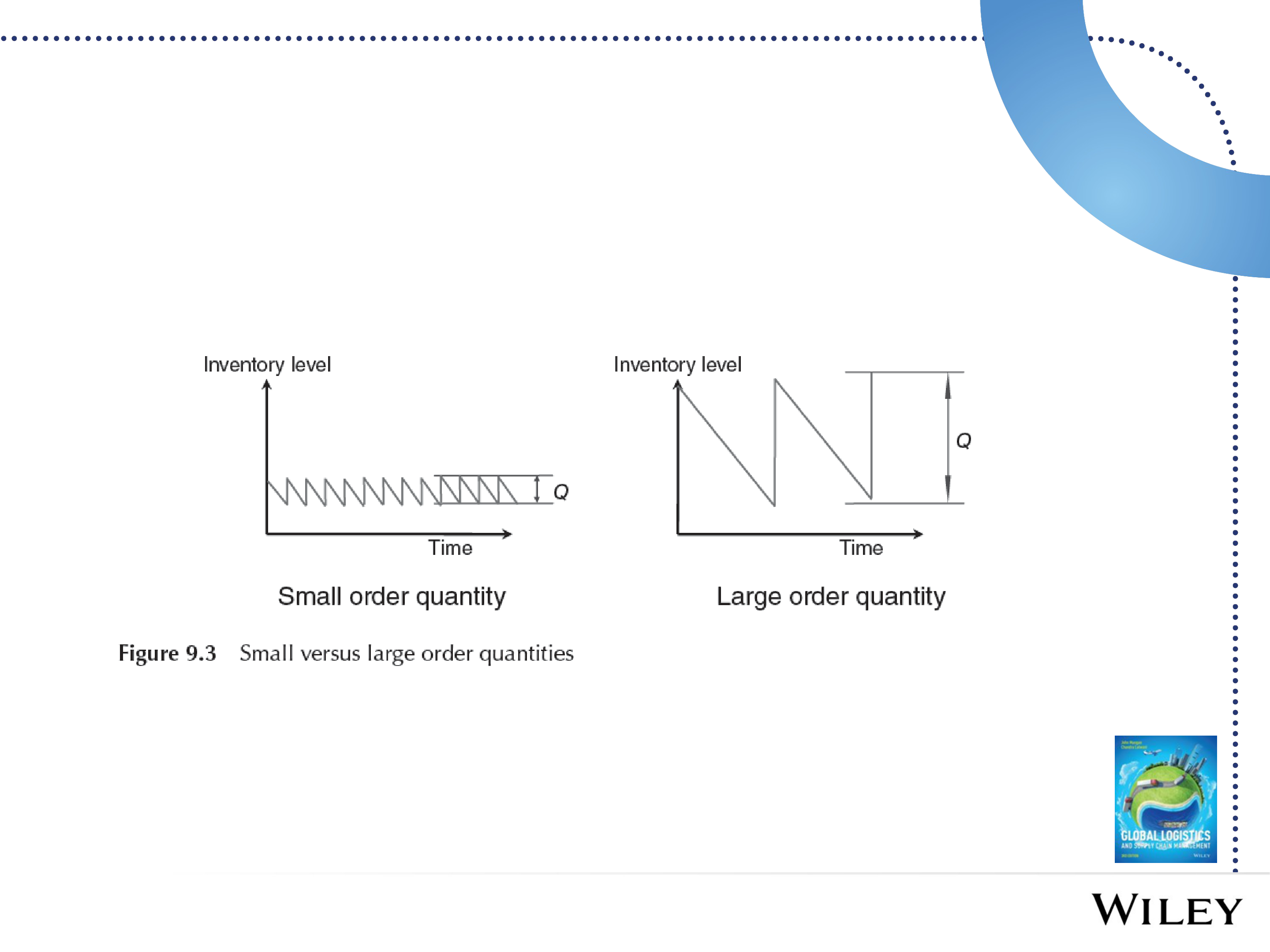

Small versus large quantities

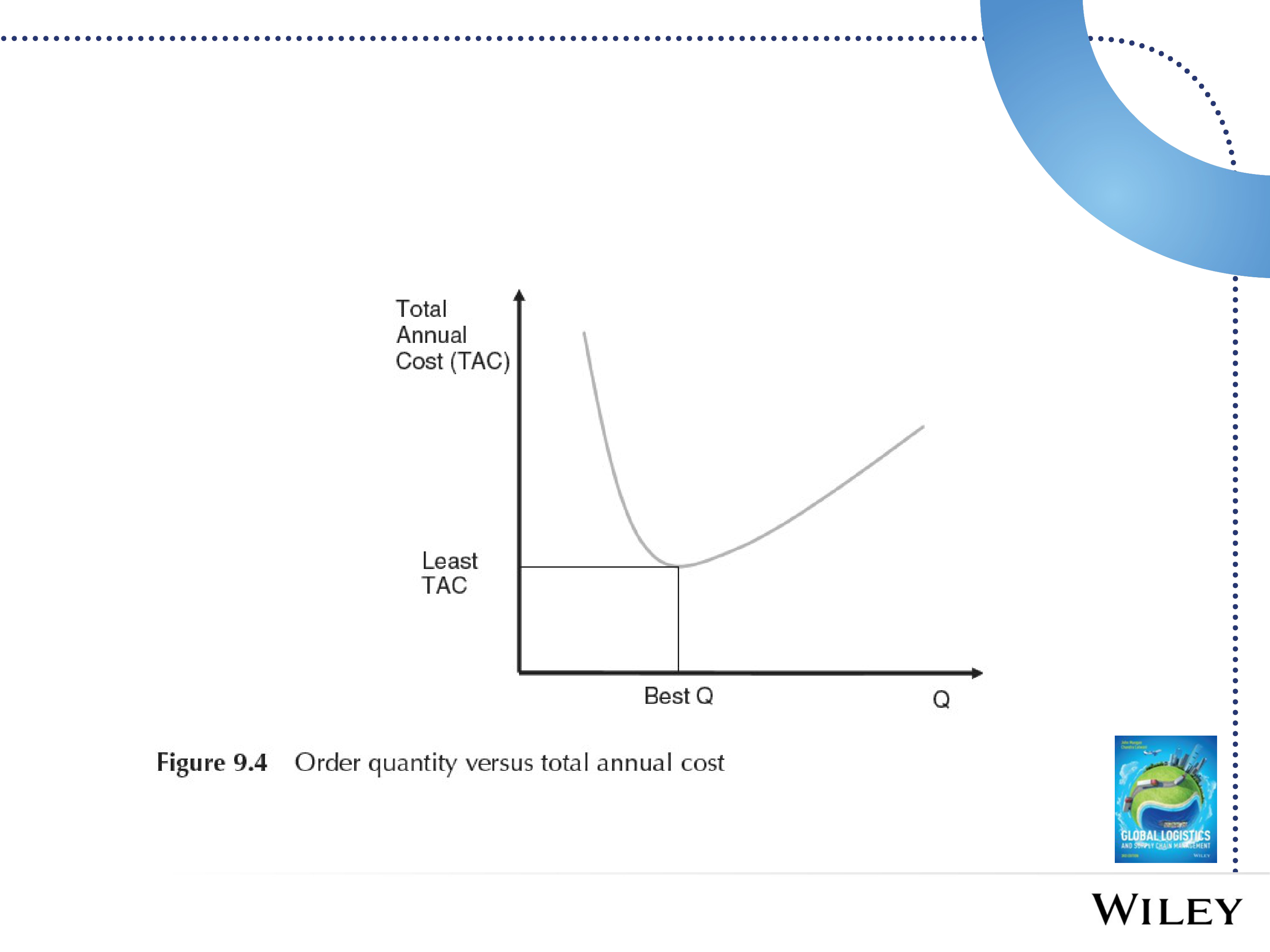

Order quantity versus total annual cost

Inventory control systems

· The periodic inventory control system: orders are reviewed periodically (not continuously as in the reorder point system), after the passage of a fixed time period (T)

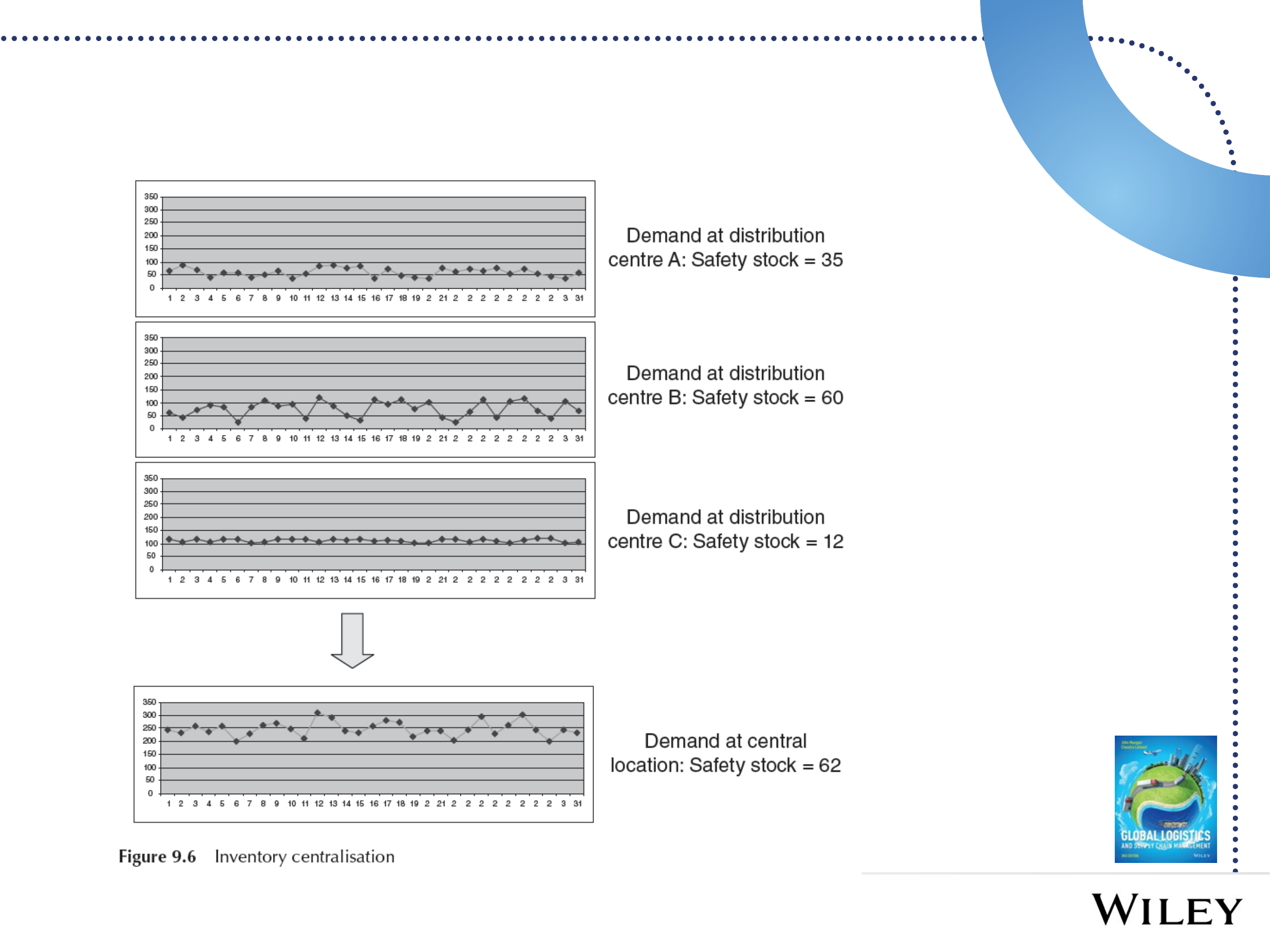

Inventory centralisation

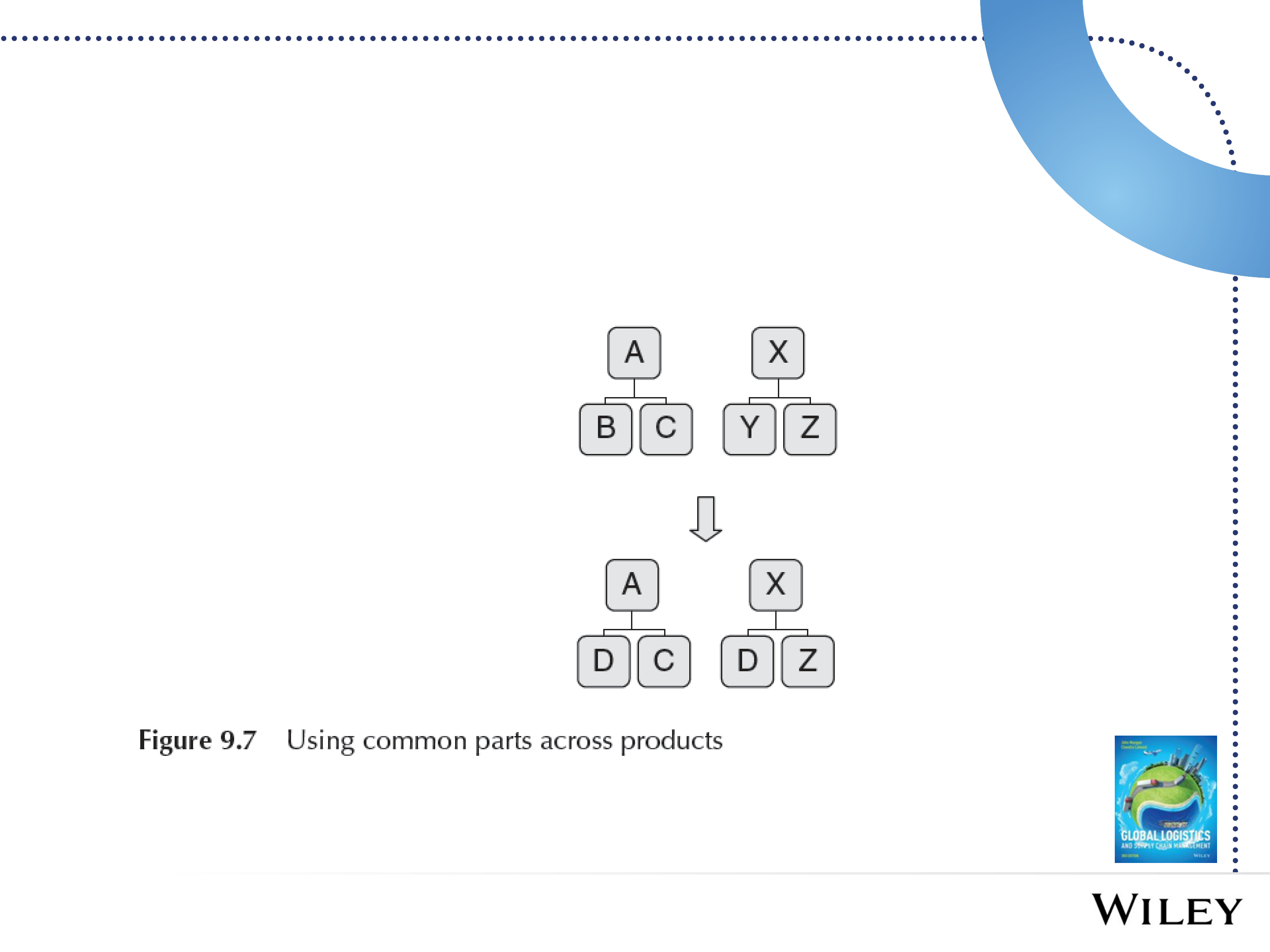

Part commonality

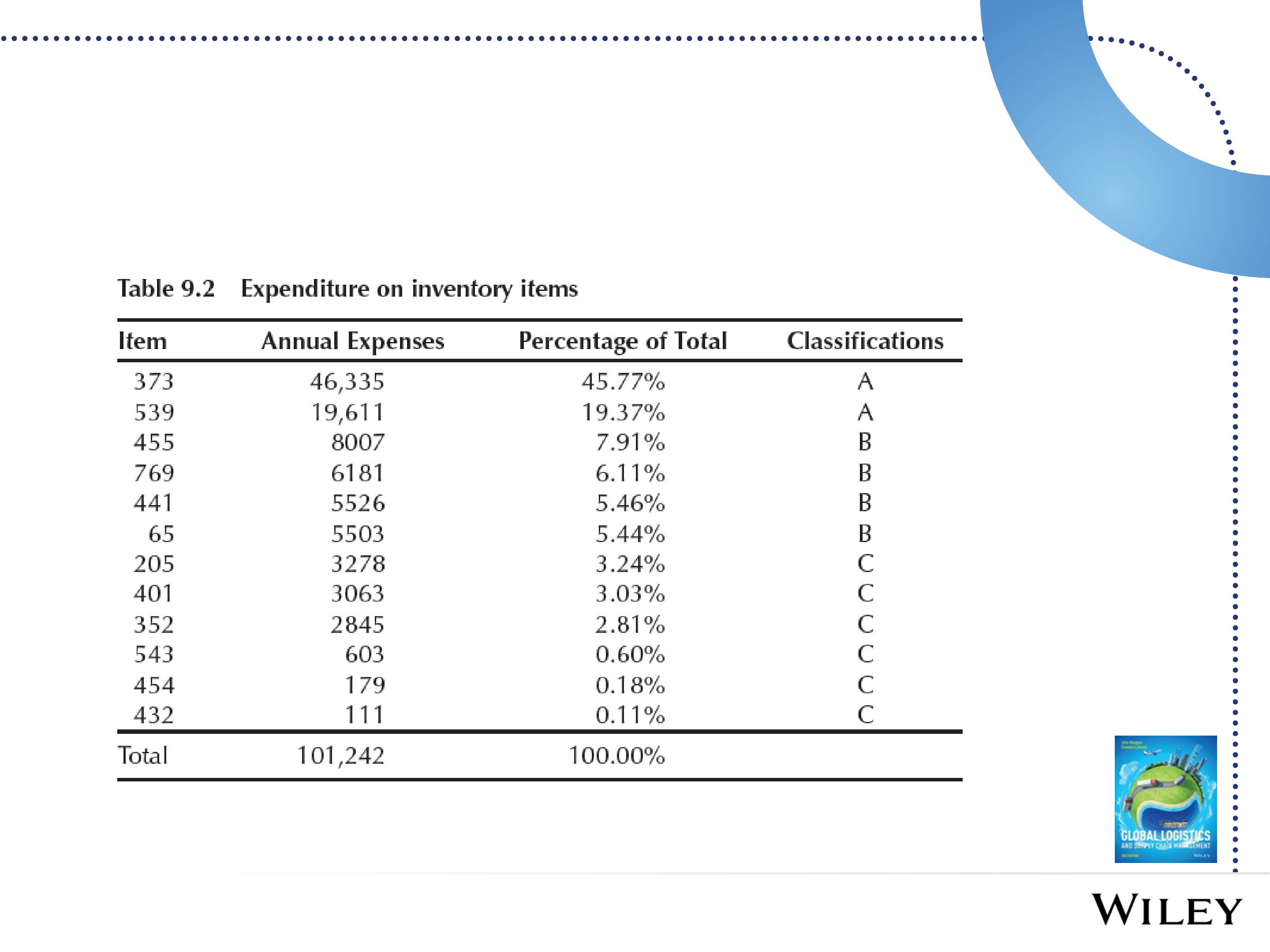

ABC analysis – expenditure on inventory items

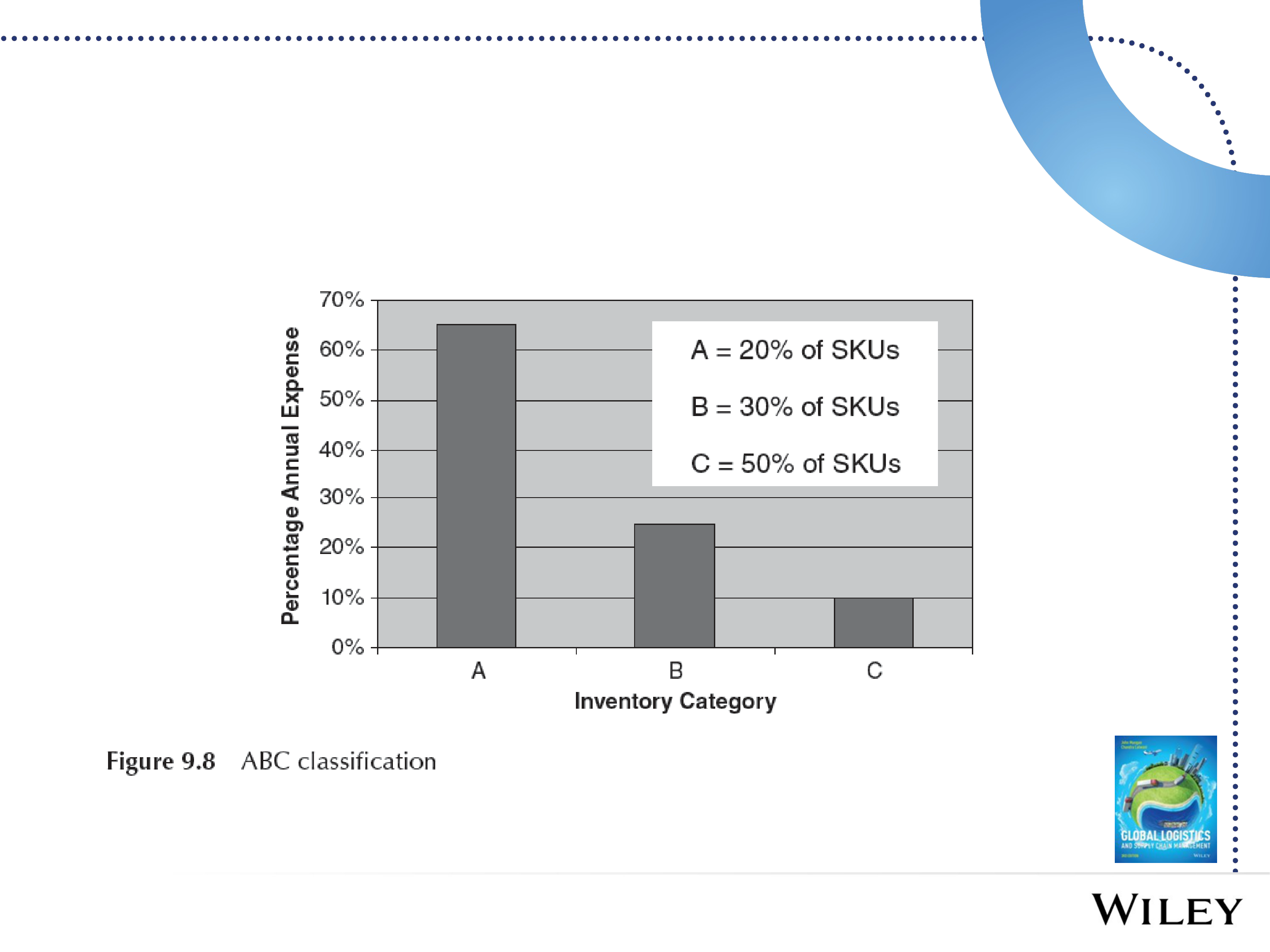

ABC classification

· Reduce variation: Wherever variation can be reduced, safety stock can be reduced, too

· Reduce lead time: When the lead time is long, we need to forecast more into the future, thus the accuracy of the forecast suffers, increasing the variability of demand and consequently requiring higher safety stock

– Small lot production

o Ordering in small quantities keeps the average inventory level small