BSBMGT608 Manage innovation and continuous improvement

Assessment Task 1

Review programs, systems and processes

Performance objective

To demonstrate the skills and knowledge required to review, evaluate and analyse programs, systems and processes.

Assessment description

Based on the case study provided, you will write a report in which you outline a performance and sustainability review strategy, evaluate the strategy, analyse performance reports and trends, and describe how you would seek advice from specialists to identify technological solutions.

Procedure

- Read the case study ‘A. C. Gilbert’ in Appendix 1.

- Analyse the information provided and prepare a report addressing the following six (6) points.

- Describe the key systems and processes used by A. C. Gilbert:

- supply chain

- operational systems

- product/service delivery.

- Analyse the three key systems and processes and develop the elements of your review strategy. Applying your knowledge of quality management and continuous improvement theory, develop performance and sustainability measures, assessment tools and techniques that you would use to evaluate the effectiveness of the three key systems and processes.

In your report, include if applicable:

- lists of key result areas (KRAs)

- lists of key performance indicators (KPIs)

- a description of performance review processes

- a sample service level agreement.

- Using the data provided for results up to 1966, for each of the three key systems, describe how each of your measures, assessment tools and techniques would monitor performance. Include specific examples or hypothetical cases to test the effectiveness of the elements of your review strategy. Write an evaluation of the effectiveness of your review strategy. Suggest improvements to your strategy.

Refer to quality management and continuous improvement theory.

- Using the data provided for results up to 1966, analyse the variances from plans and targets for the key result areas (KRAs). Include discussion on performance with regards to:

- quality – design/manufacturing

- sales

- profit

- supply chain performance (delivery)

- business growth – staff and management performance and/or turnover.

- Discuss trends relevant to the organisation. What trends did A. C. Gilbert fail to identify in the late 1950s?

Consider the strengths and weaknesses of the A. C. Gilbert Company prior to 1960. Discuss the following in your report:

- market share

- reputation

- stability

- profit

- sales

- ability to adapt to change

- customer service standards

- innovation

- employee performance

- production and manufacturing.

Apply creativity skills to identify missed opportunities to improve business performance. Describe at least one missed opportunity in detail. Include an action plan for implementing the improvement in your report.

- Imagine the company did not close in 1967 and has somehow managed to continue operations until today. Discuss the possible use of advice from specialists. What specialists could be consulted to advise on and identify new technology or electronic commerce opportunities? Consider:

- internal – engineers, production staff, manufacturing staff, sales personnel, human resources personnel

- external – marketing consultants, advertising experts, engineers or designers, IT consultants.

- Describe the key systems and processes used by A. C. Gilbert:

- Submit your report to your assessor as per the specifications below. Ensure you keep a copy of all work submitted for your records.

Specifications

You must provide:

- a written report submitted within agreed timeframe.

Your assessor will be looking for:

- reference to, and application of, quality management and continuous improvement theories in review strategy

- reference to and application of sustainability practices in review strategy

- analytical skills to identify improvement opportunities

- demonstration of creativity skills to think laterally and identify improvement opportunities.

Adjustment for distance-based learners

- No variation of the task is required.

- Documentation can be submitted electronically or posted in the mail.

Appendix 1 A. C. Gilbert

History 1909–1961

Alfred Carlton Gilbert was an inventor and a toy manufacturer who invented the Erector engineering set. His original company, The Mysto Manufacturing Company, was founded in 1909 to manufacture the Erector set. In 1916, Mysto became the A. C. Gilbert Company and gained a reputation for producing quality toys.

By the 1950s, A. C. Gilbert was one of the leading toymakers in the United States, with annual sales regularly topping $17 million. This was an outstanding achievement for a relatively small company.

In 1961, A. C. Gilbert, Senior, died, leaving the company in the hands of his son, A. C. Junior. At the time A. C. Junior took over the firm, the company was established as a traditional, reliable and profitable manufacturer of educational toys.

Product lines and rationale

- A. C. Gilbert produced train sets, but their most popular lines were chemistry sets, microscopes and their best seller, the Meccano-like Erector engineering sets that had been popular with children for more than 50 years.

- A. C. Gilbert toys were not cheap. They were high quality, solidly crafted and made to endure. Parts and packaging were designed to last for many years, with the Erector set packaged in long-lasting metal boxes. The focus was on educational toys, primarily aimed at boys rather than girls. The company had a limited range, but what they did manufacture was top-quality and highly regarded.

Systems and processes

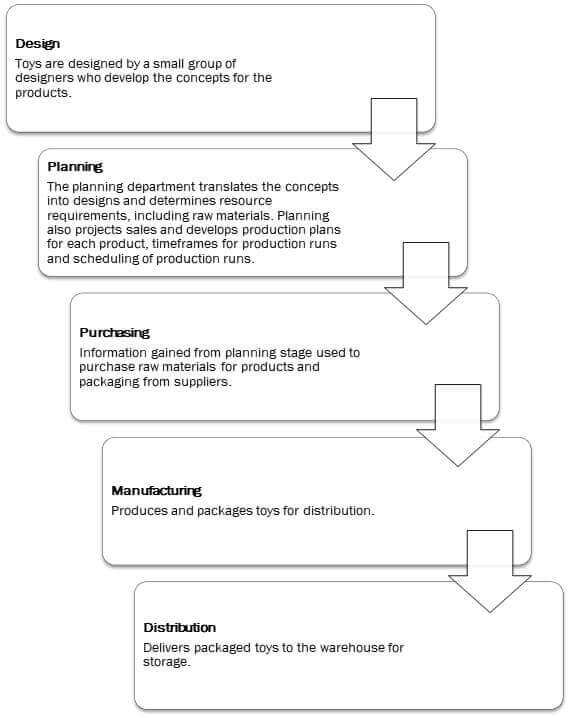

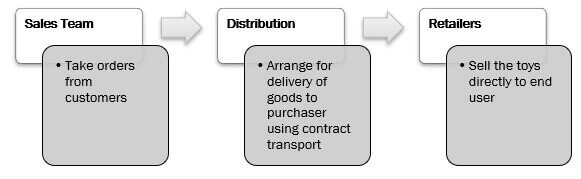

A. C. Gilbert was a small company. The following model demonstrates the systems and processes in place.

Note: These flow charts have been included for assessment purposes only, and may not accurately reflect the actual processes in place at A. C. Gilbert.

History 1961–1967

As the 1950s moved into the 1960s, there were huge cultural changes across the world. The fifties were a very traditional era of family values and morals, conservative and staid. Then came the ‘swinging sixties’. The sixties were a time of rapid change both technologically and culturally. Old-fashioned values gave way to new moral freedoms.

Where the fifties represented solidarity and familiarity, the sixties embraced change. Everything was bolder, brighter and more daring. A new young president and rising social activism by youth saw changes in clothing, music and interests. Young people rebelled against the values of their parents and embraced a more fast-paced, exciting and riskier lifestyle.

Changes to the toy industry

Cultural changes had a huge impact in western toy markets. Barbie and Action Man became ‘must have’ toys. Girls moved away from baby dolls and cots and wanted dolls that were more grown up, modern and trendy. They wanted dolls they could dress in the latest fashions and who had exciting ‘careers’, boyfriends and cars of their own. Boys were moving away from the traditional train sets and towards exciting new slot-car racing sets and action figures from popular movies and television shows.

Traditionally, toy advertising had been done via magazine promotions, but the sixties brought in a new phenomenon: television advertising. A hugely powerful medium, TV advertising became increasingly ‘hard sell’, with toys heavily promoted, especially in the lead up to Christmas. Children wanted the latest and greatest toys that they saw in these advertisements, and they put pressure on their parents to buy, which their parents did.

Retailing of toys during this period reflected a shift in retailing in general. Small, specialty retailers with experienced and knowledgeable staff were going out of business, replaced by large discount stores catering for the mass market. The goal of this type of retailer was to turn over stock. Heavily advertised lines were in demand, and that is what they would stock. Cheap was in, and giant retailers were after a quick profit from easily saleable, inexpensive products. They weren’t interested in catering to a niche market by stocking more expensive, harder to shift lines.

Packaging was bright and colourful in order to attract children growing up in a world of colour TV, hypercolour clothing and visual stimulation provided by the swinging sixties.

Effects on A. C. Gilbert

As a small, traditional company, A. C. Gilbert was slow to react to these changes. It may have been that they were not aware of the changes or were overly confident that their good name and reputation were sufficient to continue trading as before. The consequences of this short-sightedness soon became apparent.

1961 (figures approximate)

L/Y Sales | Actual sales | Difference | Profit |

$12.6 million |

$11.5 million | ($1.1 million) | $20,011.00 |

This drop in sales was also reflected in a fall in the share price of the company.

Outcomes

As a result of the falling profits and share price, the company became attractive to an opportunistic businessman, Jack Wrather. Jack Wrather was an independent television producer who had made his money producing the popular programs ‘Lassie’ and ‘The Lone Ranger’. Jack Wrather wanted to purchase a successful business and felt that in

A. C. Gilbert, he had the opportunity to use his knowledge of popular entertainment and apply it to the production of toys. He purchased 52% of A. C. Gilbert for $4 million and immediately set about making his mark on the company. A. C. Junior stayed on as Chairman but his influence was minimal.

Actions taken by Jack Wrather

- Set a goal to achieve sales of $20 million in 1963.

- Replaced the top A. C. Gilbert executives with his own people.

- Initiated a massive advertising campaign.

- Increased sales staff by 50%.

- Instructed sales staff to adopt an aggressive sales approach.

- Introduced 50 new toy lines, raising the lines to 307.

- Changed the focus from traditional boys' toys to ranges for pre-school children,

and dolls and other toys aimed at girls between the ages of 6 and 14. - Spent $1 million on changing the packaging for all lines to brighter, more

colourful boxes.

Performance report

Year | Sales | Difference from previous year | Profit/loss |

1961 | $11.5 million | ($1.1 million) | $20,011.00 |

1962 | $10.9 million | ($600,000.00) | ($281,000.00) |

1963 | $10.7 million | ($200.000.00) | ($5.7 million) |

1964 | $11.4 million | $700,000.00 | ($2.6 million) |

1965 | $14.9 million | $3.5 million | ($2.9 million) |

1966 | $12.9 million | ($2 million) | ($12,872,000.00) |

1967 |

A. C. Gilbert closed (1909–1967) | ||

Key milestones

1962:

- Jack Wrather purchased 52% of A. C. Gilbert.

- Replaced existing executives with his own people.

- Increased sales staff by 50%.

- Implemented extensive television advertising.

- Set an organisational goal to achieve sales of $20 million for 1963.

- Company recorded a loss of $281,000.00.

- Introduced 50 new lines in less than 12 months, using existing engineers and production departments who lacked training and experience in the new product range.

- Repackaged existing lines at a cost of $1 million.

1963:

- Sales and profits down on previous year.

- Anticipated drop in profits due to expansion and cost of establishing new lines.

- Sales fell short of expectations.

- Decline in quality of toys – feedback indicated products poorly made and designed (dolls did not even come with a change of clothing).

- New range perceived by customers as poor quality and overpriced – not value for money nor attractive to the target market.

1964:

- Jack Wrather fired most of the top management team he had hired two years previously.

- Crisis management led to multiple changes and dramatic measures being taken and then changed – often one measure contradicting the previous.

- Jack Wrather hired new CEO – Isaacson.

- Isaacson fired the entire sales team.

- Isaacson made huge cutbacks in spending.

- Sales were channelled through independent manufacturer’s reps, which was cheaper than maintaining an in-house sales force.

- Long-standing relationships soured as the independent reps worked on commission and pushed sales, with no interest in maintaining or building relationships with customers.

- C. Gilbert had built its success on personal service and building relationships – that was destroyed within 12 months.

- C. Gilbert Junior died and is replaced as Chairman by Jack Wrather. Isaacson assumes the role of President.

- Prior to Christmas, many of the previous year’s failed products were deleted and 20 new items introduced.

- Reduced the price of core lines such as the Erector set from $75 to $20, but quality also impacted – cardboard box instead of metal boxes, and brittle parts instead of sturdy, long-lasting parts.

- Sales increased and there was some degree of optimism.

1965:

- Sought to capitalise on popular crazes such as James Bond and The Man from U.N.C.L.E. by introducing action figures for Christmas.

- Due to internal strife and staff cutbacks, the new lines were not delivered to the stores until after Christmas.

- Operated on a skeleton workforce.

- Due to lack of staff, A. C. Gilbert was unable to implement changes or introduce new lines quickly enough to capitalise on trends.

1966

- Increased advertising spending to $3 million.

- Introduced point-of-purchase display products supplied to dealers free of charge.

- Borrowed $6.25 million, granted on the event that the company made a profit in 1996.

- Company made a loss of $12,872,000.00.

1967

- February – A. C. Gilbert closed its doors after 58 years.

Note: This case study is a true story. You may wish to read more about this organisation or to conduct additional research online.

Reference material

- Tibballs, G., 1999, Business blunders, ‘A. C. Gilbert: Toy Story’, Robinson Publishing Ltd, pp. 43.

Assessment task 2

Develop options for continuous improvement

Performance objective

To demonstrate the skills and knowledge required to develop options for continuous improvement.

Assessment description

Based on the case study provided, you will develop a performance improvement strategy, brief a team of peers on the strategy, develop the strategy and encourage innovation within the group session, and incorporate results of consultation into strategy. You will develop risk and cost-benefit analyses which you will submit to your assessor for approval.

Procedure

- Read the case study ‘A. C. Gilbert’ (Appendix 1). Assume no improvements have been made and the company is still operating in the same way today as when it closed in 1967.

- Consider the following scenario:

Your manager, as per organisational processes for continuous improvement, has asked you to develop a performance improvement strategy, brief the management team, develop the idea with the team, seek the team’s approval and seek final approval from your manager.

- Develop a one-page performance improvement strategy related to competitiveness. Include:

- strategic goals

- description of proposed process or amendment to current process

- brief explanation of how proposal will improve performance and competitiveness

- KRAs, KPIs, targets.

- Prepare to deliver a 20–30 minute management team briefing and consultation session:

- distribute your proposed strategies to team (team members may be other learners, or other group approved by assessor)

- ask team to consider strategy, including:

- pros and cons

- changes or improvements to strategy

- preparing to discuss changes or improvements at team briefing and consultation session.

- agree on a time for session (agree on time with assessor to ensure assessor can observe session).

- Lead session:

- discuss options and work through group suggestions

- use creative techniques to generate or develop ideas

- work through implications of suggestions to trial them

- encourage group to point out issues or potential problems during trialling

- if and when applicable, accept failure of ideas and recognise successful ideas.

- Summarise results of session and seek group’s approval for amended strategy.

- Incorporate results of session into revised strategy.

- Develop a risk analysis for strategy.

- Develop a cost-benefit analysis for strategy.

- Arrange a time to meet with assessor (in role of your manager) to discuss strategy, risk and cost-benefit analyses. Explain costs and benefits. Seek approval for strategy.

- Submit documents to your assessor as per the specifications below. Ensure you keep a copy of all work submitted for your records.

Specifications

You must provide a:

- one-page performance improvement strategy

- 20–30 minute team briefing and consultation session (team members may be other learners, or other group approved by assessor)

- revised one-page performance improvement strategy

- written risk analysis

- written cost-benefit analysis.

Your assessor will be looking for:

- application of quality management and continuous improvement theories in improvement strategy

- demonstration of creativity and innovation theories in group consultation

- application of organisational learning principles

- demonstration of cost-benefit analysis

- demonstration of risk management

- analytical skills to identify improvement opportunities

- demonstration of creativity skills to think laterally and identify improvement opportunities that come from group

- demonstration of learning skills to develop options for continuous improvement

- demonstration of teamwork and leadership skills to lead group session.

Adjustment for distance-based learners

- No variation of the task is required.

- A follow-up interview may be required (at the discretion of the assessor).

- Documentation can be submitted electronically or posted in the mail.

- Briefing and consultation session may be conducted and observed live or via an appropriate teleconferencing tool.

Appendix 1 – A. C. Gilbert

Assessment task 3

Implement innovative processes

Performance objective

To demonstrate the skills and knowledge required to implement innovative processes.

Assessment description

Based on part 1 of the case study provided (see Appendix 1), you will develop an implementation plan to embed a new process. Based on part 2 of the case study (see Appendix 1), you will need to amend your plan to ensure success.

Procedure

- Turn to the case study ‘Implement an innovative process’ (Appendix 1).

- Review ‘Part 1 – Implementation’. Examine all aspects of the new process to be implemented.

- Develop action plans for 1) transition, and 2) communication. In each action plan, include:

- activities, objectives, measures (KPIs), timeframes

- activities to promote the process and sustainability

- activities to reduce any negative impact on people.

- Develop at least two contingency plans related to possible implementation issues you foresee in relation to activities in your action plans.

- Review ‘Part 2 – Follow up’. Examine implementation issues and failures.

- Amend your action plans and contingency plans to address implementation failures.

- Develop a schedule for evaluation and continuous improvement. Include regularly scheduled:

- evaluation activities, regularly repeated over a suitable timeframe

- evaluation activities to capture learnings from all work activities

- activities to embed learning into work processes.

- Submit documents to your assessor as per the specifications below. Ensure you keep a copy of all work submitted for your records.

Specifications

You must provide:

- action plans for transition, communication

- two contingency plans related to transition and communication action plans

- amended action plans and contingency plans based on data in part 2 of the case study

- evaluation and continuous improvement schedule.

Your assessor will be looking for:

- application of quality management and continuous improvement theories to planning and scheduling activities

- application of creativity and innovation theories to scheduling evaluation and continuous improvement

- application of organisational learning principles to continuous improvement planning

- application of sustainability practices to planning/revising plans

- analytical skills to identify improvement opportunities based on data in case study

- demonstration of creativity skills to think laterally and identify improvement opportunities to revise activities based on data in case study

- demonstration of learning skills to develop options for continuous improvement from data in case study.

Adjustment for distance-based learners

- No variation of the task is required.

- A follow-up interview may be required (at the discretion of the assessor).

- Documentation can be submitted electronically or posted in the mail.

Appendix 1– Implement an innovative process

Part 1 – Implementation

John Jones, a Production Manager at A. C. Gilbert, has developed an idea for improving efficiencies in the manufacturing process at A. C. Gilbert. The idea came as a result of the innovative ideas program, and John has successfully trialled the program on one line in the processing plant.

The program has been evaluated and found to be successful, and you are now in the process of implementing the program company-wide.

Overview of the program

The goal of the program is to increase productivity, reduce waste, improve sustainability, and reduce errors on production lines by 20% by allocating specialist team members to individual lines.

A secondary goal is to reduce staff turnover from an average of 32% per annum to 20% per annum, thus improving the skill levels and efficiencies of the plant and reducing costs in recruiting and training new staff.

Production staff and process workers will be divided into five different teams. Each team will be responsible for the manufacturing of five product lines. Team members will only work on their specialty line, and rosters will be altered to ensure adequate staff on each line during the 12-hour production cycle. This may involve changes to staff rosters, in some cases by implementing 12-hour shifts, but will not impact on earnings or result in the loss of any hours of work.

John also suggested involving teams in goal setting and objective setting for their own product lines. Each month they meet to develop production and error rate projections for the next, with a goal to continuously improve both rates to achieve a maximum of 4% error rate and a 40% increase in productivity within 24 months. Current error rates are at 22%.

To incorporate this change, production lines will be closed for 48 hours for retooling. During this period, staff will be re-trained in the production of their designated lines by shift supervisors. Training required will include technical training, motivational training and quality control procedures along with goal and objective setting workshops.

Costs

It is projected that the costs incurred for the change will be:

Development costs | |

Initial trial | $150,000 |

Implementation costs | |

Retooling the production line Training Loss of productivity | $1.2 million $20,000 $50,000 |

|

Ongoing costs | |

Initial errors and reduced productivity | $150,000 |

Anticipated savings

By implementing the above measures the following savings have been budgeted:

- savings of $300,000 per annum in staff turnover costs

- savings of $1 million per annum in lost productivity and errors

- savings of $200,000 per annum in service and repairs costs to equipment.

Benefits and concerns

During the trial, a number of advantages and concerns were identified. There were initial fears that staff would become bored and complacent, continually producing the same lines. Analysis during the pilot found that, after the first week, staff became quite ’proud‘ of their output and felt a degree of ownership for the lines they were responsible for. Morale improved in a team environment.

Employees were initially reluctant to participate in setting their own error and productivity targets. They tended to overestimate the percentages and did not wish to commit to large improvements. Managers feel it will take some time and training in understanding the financials and operational reports for them to set realistic targets.

Many employees lack formal education and some have limited English, which was also an area of concern when trying to involve them in what they perceived to be ‘management decisions’. This style of management is a huge change in the workplace. Most employees were used to being lectured for making mistakes, rather than encouraged to participate in decision-making and feeling like they have some ownership of the process and outcomes. There is some reluctance and anxiety involved and a degree of resistance from some long-term employees, who feel they are being asked to do a management job and should be paid accordingly. Management fear there could be some industrial relations implications.

Other concerns revolve around productivity levels during the transition. It is understood that it will take some time for employees to operate at full productivity, as they will be working on new production lines and different products. Concerns that deliveries won’t be met and customers will be disadvantaged are key concerns for management.

From a technology standpoint, the new production lines will be faster and more efficient. However, the current service technicians are used to the old lines and lack the experience to service and maintain the new equipment. It is possible that breakdowns could impact on production targets.

Part 2 – Follow-up

Make the following assumptions:

- The new program has been in place for eight weeks with the following outcomes:

- productivity has decreased by 8% to 66%

- delays on the line have increased by 10%

- waste has increased by 10%

- error rates have fallen by 2% to 20%

- 15 out of 300 staff have resigned since the new program was introduced, including two shift supervisors.

- After 16 weeks:

- productivity remains at 66%

- delays on the lines have improved and are now at pre-change levels

- error rates have remained steady at 20%

- staff levels have remained steady.

- The following comments were raised at a staff forum held two months after the implementation.

- New machines are very different; training was not sufficient.

- Employees feel that figures don’t mean much to them – they are struggling to understand what % rates have to do with their day-to-day workload.

- Employees understand the importance of sustainability, but have no idea how to apply sustainable practices to workplace or amend own work practices to make them more sustainable.

- New rosters have been unpopular with some employees.

- 12-hour shifts were introduced to keep teams together but they are causing difficulties for staff with regards to managing their families.

- Longer shifts are also resulting in people becoming tired and making errors.

- The OHS representative is concerned that injuries might increase as a result.

Diploma Courses in Australia

- ACC203 Management Accounting

- ACC703 Accounting Information

- BSB61015 Advanced Diploma of Leadership

- BSB60515 Advanced Diploma of Marketing

- BSBADM502 Manage Meetings

- BSBADM502 Manage Meetings Answers

- BSBADM506 Manage business document design

- BSBCOM603 Plan and establish compliance management

- BSBFIM601 Manage Finances Prepare budgets

- BSBFIM601 Manage Finances Monitor and review budget

- BSBHRM509 - MANAGE REHABILITATION OR RETURN

- BSBHRM512 develop and manage performance

- BSBINM601 Manage knowledge and information

- BSBINN601 Lead and manage organisational change Task 1

- BSBINN601 Lead and manage organisational change Task 2

- BSBINN601 Lead and Manage Organisational Change Task 2

- BSBINN601 Lead and manage organisational change Task 3

- BSBMGT403 Assessment Answers

- BSBMGT502 Assessment 1

- BSBMGT502 Assessment 2

- BSBMGT502 Assessment 3

- BSBMGT502 Assessment 4

- BSBMGT517 Assessment 2 - Operational Plan

- BSBMGT517 Manage Operational Plan Assignment Answers

- BSBMGT605 Provide leadership across the Organisation T1

- BSBMGT605 Provide leadership across the Organisation T2

- BSBMGT605 Provide leadership across the Organisation T3

- BSBMGT605 Provide leadership across the Organisation T4

- BSBMGT608 Manage innovation and continuous

- BSBMGT616 Develop and implement strategic plans

- BSBMGT617 Develop and Implement A Business Plan

- BSBMGT624 Develop and implement corporate social

- BSBMKG502 Establish and adjust the marketing mix

- BSBMKG609 Develop a marketing plan

- BSBPMG505A Manage Project Risk

- BSBPMG505A Manage Project Quality

- BSBRSK501 Manage Risk Answers

- BSBSUS501 Develop workplace policy

- BSBSUS501 Develop workplace policy and procedures

- BSBSUS501 Develop workplace policy and procedures

- BSBSUS501 Develop workplace policy and procedures

- BSBWHS605 Develop, implement and maintain WHS

- BSBSUS501 Develop workplace policy and procedures

- BSBWRK510 Business Services Training Package

- BSBWRK510 Manage employee relations

- BUS707 – Applied Business Research

- BMA583: Managing People and the Employment

- CHCAGE001 Facilitate the empowerment of older people

- CHCAGE002 Implement falls prevention strategies

- CHCAGE005 Provide support to people living with dementia

- CHCCCS011 Meet personal support needs

- CHCCCS015 Provide individualised support

- CHCCCS015 Provide individualised support Assessment

- CHCCCS023 Support independence and well being

- CHCCOM005 Communicate and work in health

- CHCDIV001 Work with diverse people Assessment

- CHCLEG001 Work legally and ethically Assessment

- CHCPAL001 Deliver care services using a palliative approach

- CHCPOL003 Research and apply evidence to practice

- CHCDIS002 Follow established person-centred behaviour

- CHCDIS003 Support community participation and social

- CHCDIS007 Facilitate the empowerment of people with

- CHCDIV001 Work with diverse people

- CHCLEG001 Work legally and ethically

- CHCLEG001 Work legally and ethically Learner Guide

- CHCLEG001 Work legally and ethically Learner Workbook

- CHCWHS312A Follow WHS safety procedures for direct care

- CPCCBC5011A Develop and Implement an Environmental

- CPCCBC5011A Manage Environmental Management Practices And Processes In Building And Construction

- CPCCBC5003A Construction Project Planning

- CPCCBC5018A Apply structural Principles Medium rise

- HLTAAP001 Recognise healthy body systems Assessment

- HLTAAP001 Recognise healthy body systems

- HLTAAP001 Recognise healthy body systems Case Study

- HLTAAP001 Recognise healthy body systems Learner Guide

- HLTAAP001 Recognise healthy body systems Learner

- HLTWHS002 Follow safe work practices for direct client care

- HLTWHS002 Follow safe work practices for direct client care

- HLTWHS002 Follow safe work practices for direct client care

- HLTWHS002 Follow safe work practices for direct client care

- Manage project risk

- MITS5002 Software Engineering Methodology

- MKT01907 Tourism And Hospitality Management

- SHBXWHS001 Apply safe hygiene, health and work practices

- SITHKOP002 Plan and cost basic menus Learner Guide

- SITHKOP002 Plan and cost basic menus Learner Workbook

- SITHKOP006 Plan Catering for events or Functions

- SITXCCS007 enhance customer service experiences

- SITXCCS007

- SITXHRM003 Lead and manage people

- SITXINV004 Control stock

- SITXFIN003 - MANAGE FINANCES WITHIN A BUDGET